Spartan Knife Block

by

Stephen Taylor

(IC: homeowner)

I saw this Knife Block on the web and thought it looked cool. However the maker had used all sorts of tools that were way out of my reach (CNC mill,Laser cutter etc). So I thought I would see if I could make one using tools that the average handyman might possess. There was a bit of experimentation involved and a few lessons learned along the way. If (and it is a big if) I ever make another I may do it differently. I gave this one away afterwards!

The original idea and plans for this were by Christian Kneull of Estlcam.com

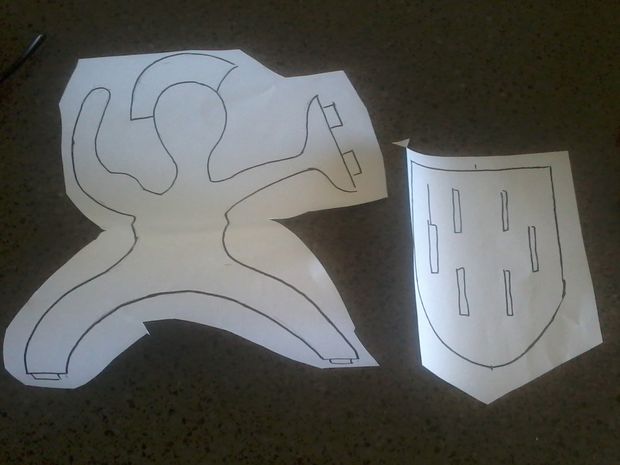

The Design

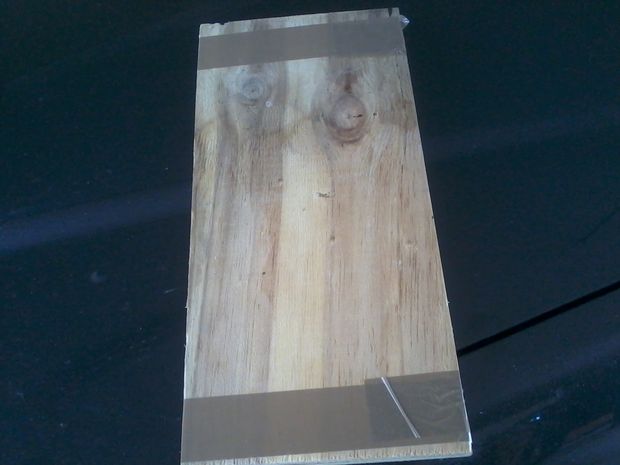

The Wood

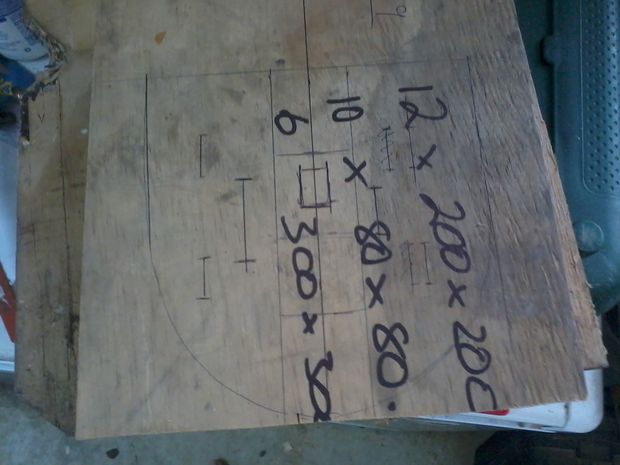

Stick them down

Cut it Out

Glue them all together

The Base

The Shield

Ready to Assemble

Insert the magnet

Cut Slots and Add knives

Enjoyed the project?

Published January 1st, 2016 7:58 PM

Comments

Join the conversation

4 of 42 comments

-

That is really cool ...I like that ...you did an awesome job ....

Maude LaFountain

on Jan 13, 2017

Maude LaFountain

on Jan 13, 2017

-

Thank you

Stephen Taylor

on Jan 13, 2017

Stephen Taylor

on Jan 13, 2017

-

-

-

Aiokersonalicea1

on Oct 14, 2018

Aiokersonalicea1

on Oct 14, 2018

You did a great job!

Whoever you gave it away to Got a Blessing!

I love the fact that it is an unusual knife holder.

-

Stephen Taylor

on Oct 14, 2018

Stephen Taylor

on Oct 14, 2018

Thank you

-

-

Frequently asked questions

Have a question about this project?