Make a Farmhouse Table With Traditional Joinery and Breadboard Ends

by

Ty Moser

(IC: vlogger)

1 Material

$1500

30 Hours

Medium

I love walnut and it's not every day I get to use such a large amount of it to make a custom farmhouse table out of walnut wood with traditional mortise and tenon joinery and drawbored breadboard ends.

{

"id": "4047894",

"alt": "",

"title": "",

"video_link": "https://www.youtube.com/embed/y-zQSZ1tluw",

"youtube_video_id": "y-zQSZ1tluw"

}

{

"width": 634,

"height": 357,

"showRelated": true

}

Check out the video above to see the entire build process to go along with the steps below.

Unless you buy fully dimensioned wood you'll need to start by milling the rough cut lumber by getting two perpendicular sides on a joiner and parallel sides using a planer and table saw. If you don't have these tools, some hand plans would be a good alternative as well as a good workout.

After laying out and figuring out the order I want the boards in for the top, I like to start the glue up in sections. Especially since the top of this table was so thick and heavy.

On this table I used a biscuit joiner to help with alignment but thats not required and doesn't add any strength. On the flip side, you could also use dowels and even a domino if you are so lucky.

When starting with rough cut or even dimensional lumber it's inevitable that you'll have some knot holes or cracks that might need to be filled. I like to use a slow curing epoxy like West Systems and a little dye to help fill and stabilize the wood.

After gluing the separate pieces of the table together it's time to clamp them all up into a large heavy piece. I don't worry about final dimensions until after this glue up at which point I use a circular saw and guide to get a perfectly square top.

When making the bread board ends, you can use a chisel and mallet or you can take a short cut like I did by utilizing a plunge router and edge guide.

{

"id": "4049575",

"alt": "",

"title": "",

"video_link": "https://www.youtube.com/embed/R2y5aDdQsgk",

"youtube_video_id": "R2y5aDdQsgk"

}

{

"width": 634,

"height": 357,

"showRelated": true

}

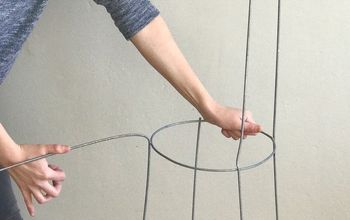

The drawbored joinery on the breadboard ends is pretty straight forward but can be slightly confusing if you've never seen it before. I have this descriptive video on the entire process which should help clear things up.

If you don't want to watch the video, the center dowels are glued and the outside ones are floating to let the table expand and contract. The drawbored effect comes from the dowels bending around the holes to suck in the breadboard.

To put a light taper on the inside of the legs, I utilized a bandsaw to get a rough angle and finished it off with a hand plane to smooth it off and bring it down to the line.

Each leg got a mortise on both inside corners which the tenon on the aprons fit into.

The mortises were first marked and drilled out to remove most of the material and then cleaned up with chisel. The tenons were rough cut using a table saw and bandsaw and finished with a block plane to ensure a tight fit.

When gluing up the entire base, you'll generally find that you won't have clamps long enough. You can either utilize multiple clamps but this can sometimes mess with the alignment. Another option is to use long bar clamps or bar clamps with couples and extra bars which is my favorite method when clamping something extremely long.

The entire project was finished with a hand full of coats of wipe-on polyurethane to ensure a durable finish.

{

"id": "4049578",

"alt": "",

"title": "",

"video_link": "https://www.youtube.com/embed/yTXfOsEadxI",

"youtube_video_id": "yTXfOsEadxI"

}

{

"width": 634,

"height": 357,

"showRelated": true

}

In this video, I explain my process for utilizing thinned down wipe-on poly to get a french polish like finish. For this table, I modified the process a bit where I started off with a very thinned down mixture to help it soak in, followed by not thinned down at all to build it up and finished with a thinned down mixture with wet sanding and a rubbed on finish to make it extra smooth.

The top is fastened to the base utilizing Table Top Fasteners screwed into the tabletop and set into a saw blade's kerf cut into the table's aprons.

The last step is to enjoy your beautiful work.

If you want to see more videos from me, please check out and subscribe to my YouTube channel!

If you want to see what else I'm up to, check out my website: https://www.monolocoworkshop.com

Enjoyed the project?

Suggested materials:

- Walnut Wood (Petermans Lumber)

Published July 18th, 2017 2:16 PM

Comments

Join the conversation

2 of 26 comments

-

Elaine Sylvester

on Apr 20, 2019

Elaine Sylvester

on Apr 20, 2019

This is so stunning!

-

-

Frequently asked questions

Have a question about this project?

Very impressive work.I am in the middle of a somewhat similar table and will post the story when it is done. Your work and joinery is much more refined than mine.

I viewed your youtube video and have a questions about the bread board ends. I thought I understood the concept of perpendicular grain opening the glue joints on the table top. I have gotten around this by typical making the breadboard end being part of a leaf extensions that isn't rigidly attached to the top. Alternative I have screwed the breadboard to the tabletop thru elongated holes that allow for some movement.

You glued your breadboard to the top. Is it because you created mortised tabs that allow for the rigid attachment?

Once again- terrific work and thanks for sharing.

As a new woodworker, tolled around the internet to find out how to install a breadboard end on my table. Found your site and am impressed - will use your technique. So here is my question: I am using African Mahogany for a 15 x 50 inch table top. Will see fair amount of use so planning on using oil-based poly on it. If I apply three or four coats, will the wood expansion on the breadboards cause the poly to crack or is the poly flexible enough to withstand the wood movement?

How did you attache the two supports under the table top? Are they glued/fastened to the top or just the sides?