Homemade Seawater Soap

I make soap and I have used all kinds of things as the water in soap. From the left over water from steaming artichokes, to mashed bananas, to yogurt. You name it it can probably be used in soap. I was at the beach earlier this year and I took my empty water bottle and filled it with water from the ocean. I even picked up a bit of seaweed and dehydrated it and used a spice grinder to powder it. My final cost is less than $10. There are cost calculators that can be used to find the exact cost. Now if you need to buy the things I have listed it is going to cost a lot more to start but you could get 8 batches of soap out of that gallon of rice bran oil. You will have lots of left overs to make more. I tried to give exact links to where I got things but some things you may have to google to find like the gardenia red and blue. It isn't something my friend regularly carries as it costs around $50 a pound. Not so bad if you break it down into ounces and one ounce will probably do 10 batches of soap. Hit me up if you have any questions.

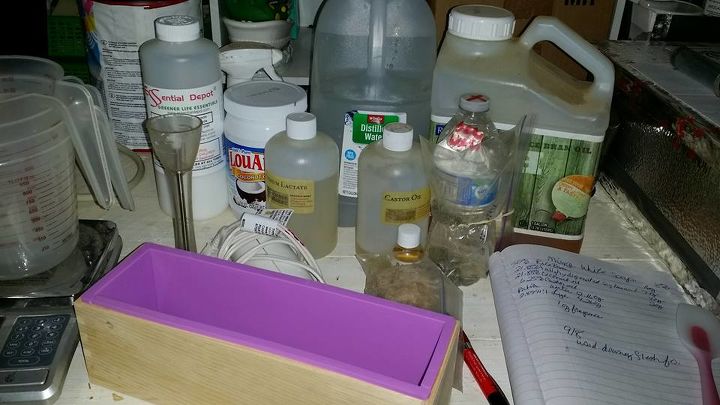

Gather your supplies. different oils, seawater, silk fibers, sodium lactate, colors, fragrance, containers for measuring, a scale, stick blender, mold and recipe. Lets get to work. Oh safety first goggles and gloves and if you are sloppy maybe an apron.

Measure your ingredients. This is my thought up recipe. I used 16 ounces of Rice bran oil, 7 ounces of Coconut oil, 7 ounces of Fully Hydrogenated Soybean oil (That is soy wax)and 2 ounces of Castor oil. I also measured out my water and lye and I chose to superfat at 8%. I'm not giving you the lye and water measurements, because you should run every recipe through a lye/soap calculator. Even an expert can make a typo. I use this one. http://soapcalc.net/calc/soapcalcwp.asp

The default there is a 5% superfat. I have dry skin so I prefer 8%. Now if you want a smaller batch than my 2 pound recipe you can enter the % of oils that I used then choose how many ounces you want your batch to be. Click calculate recipe then click view recipe and it will open your recipe in a new tab. Click it and get to work. My percents were Rice bran oil 50%, Coconut oil 21.88%, Fully Hydrogenated Soybean oil 21.88% Castor oil 6.25%. You can choose other oils if you prefer. But, you should always substitute like for like. Meaning a liquid oil for a liquid oil and a solid oil for a solid or a butter for a butter. You could use Olive or Canola in place of the Rice bran but I was out of Canola. You could use Lard in place of the Soy but you will have a softer soap. The softer the soap the faster it gets used up in the shower. And always run it through the calculator if you make a change. The lye amount can change significantly for some oils, others it may not change at all.

Melt your hard oils, sorry I forgot to take a picture of that. Usually I use the microwave but, not for a really dry oil like Soy wax, I also don't use the nuker for beeswax. This photo is the lye water. Measure your water and in a separate container measure your lye. Slowly add the lye to to the water. Never, never, never add the water to the lye. Once the lye hits the water it starts to get hot really hot, burn and blister yourself hot. If you add the water to the lye it could explode. Adding the lye to the water stinks. It makes it hard to breathe. Most people mix it outside and let it cool outside. There are stray cats outside here and I don't wish to harm them so I mix mine on the stove with the overhead vent turned on I pour the lye in the water and stir until it is dissolved. If you let it sit with out stirring well they lye can settle on the bottom and turn into glass like chips that could be caustic in the soap. So stir until you can see the bottom like the picture on the left. The left is plain distilled water, the one on the right is the seawater it stayed cloudy but I could tell by feel that the lye was dissolved. If you are uncertain you can strain your lye solution. I also added a pinch of silk fibers to my hot lye and stirred it really well it will dissolve in the solution. I then let my lye cool about an hour. Once the lye has cooled I add two teaspoons of sodium lactate. It isn't necessary but it does help the soap unmold better. OK now a bit on the kind of containers you can use. NEVER use aluminum Lye and aluminum are not a good combination. Glass should not be used the lye gets hot enough to shatter glass. Some people use Pyrex and sure you could do that but that is a ticking time bomb. Lye can etch the glass microscopically and you could make 100 batches of soap and who knows 101 or 150 times and then suddenly the cup Shatters no thank you. You can use HDPE plastic but over time you may see plastic bits floating in the lye. I bought a stainless steel pitcher off amazon for $20. Now remember goggles and gloves when mixing the lye. Safety first.

While my lye is cooling I get the oils ready. I use an HDPE plastic 1 gallon bucket when I make soap. This one came with 7 pounds of palm oil in it. Please don't lecture me about palm oil, this is an old bucket. Now there are varying opinions on when to add your fragrance. I prefer to add it to my oils. Especially if it is a fragrance you have never used. Floral fragrances for some reason accelerate trace. I once used a fragrance called Hyacinth, I poured it in my oils and as soon as I poured my lye solution it started to thicken. I didn't need to stick blend that batch I stirred it with a hard plastic spoon. Some fragrances cause soap to rice. that looks exactly what it sounds like I had that happen once it smelled like plastic not the floral scent it was supposed to be. I had to throw that one away. Now I was making 2 batches this day. This isn't the fragrance I used in my seawater soap I was taking pics of both batches and I missed taking one of the second fragrance. I used one called Black Sea in my seawater soap. It was a one ounce sample I got for a dollar. Ok add the fragrance to the oils and wait for the oils and the lye to cool to with in a few degrees of each other. If they are too hot your soap could thicken too soon

I put the stick blender in my oils first. I burp it and blend the oils a bit before I add the lye solution. If not burped properly there could be splatters and I'd rather splatter oil with out the lye solution in it. I accidentally splashed my face once it was scary. I blend until I get to a light trace. Light trace is when everything blends and you can walk away for 1 minute and it stays mixed. If you come back and see oil you aren't there yet. A thick trace looks like pudding. depending on what you are trying to do with your design you may may want a runny batch or you may want pudding. Runny is great if you are going for a delicate swirl such as the Taiwan or Feather swirl or if you are using squeeze bottles. Pudding thick is what you want for something like a spoon plop (think camouflage) or a landscape. I did those once. Today I was just pouring and swirling so it really didn't matter to me how thick it was.

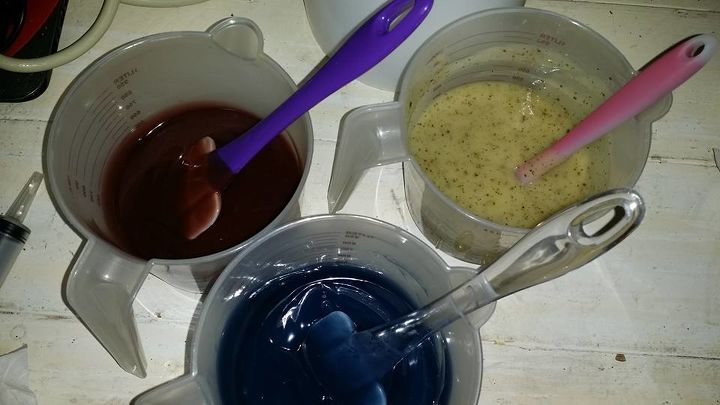

While my oils and lye were cooling I got my colors ready. I have a facebook friend who runs a small supply company, she sent me some natural colorants to try one was Gardenia red, the other gardenia blue. They cost around 6ish dollars an ounce. I used one half teaspoon of each. I put one half teaspoon of the red in one mixing bowl with a tablespoon of water and one half teaspoon of the blue in another mixing bowl with a tablespoon of water. For the third bowl I put in a couple tablespoons of my dried and powdered seaweed with enough water to moisten it. Once my soap reached trace I poured into the mixing bowls as evenly as I could. I wanted three equal colors.

Here we are all mixed and ready to pour. You can tell the blue one is pretty thick. They all were it's just easier to see in the blue.

I just poured the colors in the mold the length of the mold alternating colors, Red, white then blue. I made 5 to 6 passes with each color. I then stuck a chopstick in and made some swirls.

Chopstick making swirls. I then took the final scrapings from each bowl and plopped on top. Make fine swirls with the chopstick.

If you swirl too much it will blend the colors too much and look muddy. Here the soap molds are sitting on a piece of 1 inch thick housing insulation. I made insulating boxes to force the soap to gel.

All tucked into the insulating box. The aluminum side is the outside of the box. I didn't want that on the inside. Like I said before lye and aluminum are not a good combination. I choose to insulate my soap to force it to gel. When the soap is gelled it creates a more vibrant color then if you just left it sitting on the counter to do what it wants. Another reason to let your lye and oils cool, when you force gel the soap gets hot. If the soap is hot to begin with it can overheat and crack open. Also the fragrance can overheat and separate and leak out of the soap. Some of it may reabsorb as it cools but not all of it will and that is just a waste of money.

Now the part every creative person dreads... Clean up. You could let it just sit there for 24 hours. It will become soap. Then the next day you just wash it all up. But from my experience the dried clumps of soap are hard to clean up, especially under the blade of the stick blender. I had to soak the stuff to get it to loosen up. So what I do now is I take old kitchen towels and wash cloths and I wipe everything up. I wipe it twice. Once to get the majority off and the second time to make sure it is all off. Now if you soap often you could leave everything as is. If you don't the dried on soap that you can't see will attract dust. I usually let my stuff sit until the next day and either make more soap or wash it up and put it away. The towels I put in my laundry bucket and let it sit at least 24 hours or up until I next do a load of kitchen towels.

And here is the cut. You can see the tiny bits of seaweed in the white part. I left it incubating in the insulating box for 24 hours. I then take it out of the mold and let it sit a few hours as it is usually sweaty from being insulated. I then cut the soap into bars. They now need to cure for 6 weeks. Curing is the evaporation process of any water left. It also allows the lye to neutralize. Yes you could wash up with it right now but it will be lye heavy and drying to the skin. Your hands will feel like you just used a de-greaser to clean your stove or engine parts. These will hit 6 weeks on October 20th. You can see some of the other soaps I have made on my facebook page I'll put the link below. If you are interested in any hit me up and I'll create an etsy listing just for you.

For more soap-making tips read this guide on how to make liquid soap!

Enjoyed the project?

Suggested materials:

- Rice bran oil (Bass pro shop, on line sold out now but I found some here http://www.mackspw.com/Riceland-Rice-Bran-Fish-Fry-Oil-1-Gallon?gclid=Cj0KCQjwxdPNBRDmARIsAAw-TUllCx5IcfvyZXo6oHf26OHn-eoXtqN8SLWyZyDVCLRmevlRHX_rvjcaAlddEALw_wcB)

- Fully Hydrogenated Soybean oil (Soy wax) (http://www.candlewic.com/store/category.aspx?q=c18&title=Soy-Candle-Wax)

- Coconut oil (Walmart)

- Castor oil (http://www.candlemaking.com/crafters-choicetm-castor-oil.html?___SID=U)

- Lye (http://www.essentialdepot.com/category/soap-sodium-hydroxide.html)

- Seawater (the Pacific ocean)

- Sodium lactate (https://www.brambleberry.com/Sodium-Lactate-P5127.aspx)

- Fragrance oil (http://www.candlemaking.com/black-sea.html?___SID=U)

- Natural colorants (from a friend)

- Seaweed (the beach)

Comments

Join the conversation

-

- See 1 previous

-

Frequently asked questions

Have a question about this project?