1.7K Views

Plumbing at the Coffee Shop

by

Jeff Rayno

(IC: homeowner)

My father, Pops, and I took a bare commercial space and turned it into a state of the art coffee shop with all of its demanding plumbing requirements by local government and the health department.

*Options I considered for this project:

We considered using a contractor, however, my father is a master plumber in the state of GA so we asked him to help, and fortunately, he said yes. We also debated different layouts. The plumbing cost factor is one of the highest ticket items in a buildout so we chose to run as little pipe as possible.

Because of our minimalist approach, we chose not to run plumbing to the main checkout counter. This helped us not to have to break out cement flooring to add water and drainage for that area. All plumbing was applied to outer walls.

The law prohibits placing anything within a firewall so we mounted our water pipes on the surface of the wall rather than running the pipes under the cement floor. This also helped us save a great deal of money.

We were also able to use studor vents in our three sink compartment in the kitchen which helped us save money on PVC drainage lines. This being acceptable in the code is a great help.

All plumbing codes dictated the positioning of many items in the plan as our project had to be reviewed by the health department before we could begin. We had heard stories of other businesses trying to circumvent the process only to have the health department have them rip the whole project out.

*Questions and unexpected events that arose during the project:

We had some issues with the location of the main sewer line which was not available on any plans we were given. We were given a "guess" as to where it was. Fortunately, we dug deep enough in the proper direction and ran in to it in the perfect spot.

* Cost Comments:

Your plumbing labor cost will be high if you hire a plumber. You could expect to pay close to $90 p

*My motivation to do this project:

To create an environment that would sell high quality coffee drinks to upscale customers in a comfortable space.

*Project Steps:

Since this was not the first plumbing project we had ever done, the procedure was fairly straightforward. On a squared piece of graph paper, we outline the position of every plumbing fixture we required. From that we determined the size and type of piping necessary for a fixture to be run properly.

Once a part list was compiled, we looked at our dealer pricing books to determine the cost of each item. We had some items in our warehouse left over from past projects. Homeowners should look and see what they have on hand to avoid over buying. Various shops have similar prices, but bargains can be found in Habitat For Humanity ReStores or plumbing shops that may be closing down.

Advice:

Five Do's

1. Plan everything ahead of time

2. Research available contractors vs the cost of doing it yourself

3. Plan on their being problems and develop contingency plans.

4. Watch your budget carefully

5. Measure twice, cut once

Five Dont's:

1. Don't cut corners on proper venting of pipes

2. Don't exclude cleanouts in numerous locations. You will have future clogs.

3. Don't use cheap copper piping to save money. These spring leaks.

4. Don't proceed without the proper permits or approvals needed.

5. Don't assume that its safe to dig anywhere under a slab on commercial property, Check with power , gas and water plans first.

Materials:

200 ft 1/2 inch copper water pipe - $0.00

200 ft 3/4 inch copper water pipe - $0.00

100 ft 1 1/2 inch Drain PVC - $0.00

100 ft 1 1/4inch Drain PVC - $0.00

1 Hand Sink - $0.00

80 Gallon Commercial Water Heater - $0.00

Ice Machine - $0.00

Coffee Brewer - $0.00

Espresso Machine - $0.00

Slop Sink - $0.00

Various copper fittings - $0.00

*Options I considered for this project:

We considered using a contractor, however, my father is a master plumber in the state of GA so we asked him to help, and fortunately, he said yes. We also debated different layouts. The plumbing cost factor is one of the highest ticket items in a buildout so we chose to run as little pipe as possible.

Because of our minimalist approach, we chose not to run plumbing to the main checkout counter. This helped us not to have to break out cement flooring to add water and drainage for that area. All plumbing was applied to outer walls.

The law prohibits placing anything within a firewall so we mounted our water pipes on the surface of the wall rather than running the pipes under the cement floor. This also helped us save a great deal of money.

We were also able to use studor vents in our three sink compartment in the kitchen which helped us save money on PVC drainage lines. This being acceptable in the code is a great help.

All plumbing codes dictated the positioning of many items in the plan as our project had to be reviewed by the health department before we could begin. We had heard stories of other businesses trying to circumvent the process only to have the health department have them rip the whole project out.

*Questions and unexpected events that arose during the project:

We had some issues with the location of the main sewer line which was not available on any plans we were given. We were given a "guess" as to where it was. Fortunately, we dug deep enough in the proper direction and ran in to it in the perfect spot.

* Cost Comments:

Your plumbing labor cost will be high if you hire a plumber. You could expect to pay close to $90 p

*My motivation to do this project:

To create an environment that would sell high quality coffee drinks to upscale customers in a comfortable space.

*Project Steps:

Since this was not the first plumbing project we had ever done, the procedure was fairly straightforward. On a squared piece of graph paper, we outline the position of every plumbing fixture we required. From that we determined the size and type of piping necessary for a fixture to be run properly.

Once a part list was compiled, we looked at our dealer pricing books to determine the cost of each item. We had some items in our warehouse left over from past projects. Homeowners should look and see what they have on hand to avoid over buying. Various shops have similar prices, but bargains can be found in Habitat For Humanity ReStores or plumbing shops that may be closing down.

Advice:

Five Do's

1. Plan everything ahead of time

2. Research available contractors vs the cost of doing it yourself

3. Plan on their being problems and develop contingency plans.

4. Watch your budget carefully

5. Measure twice, cut once

Five Dont's:

1. Don't cut corners on proper venting of pipes

2. Don't exclude cleanouts in numerous locations. You will have future clogs.

3. Don't use cheap copper piping to save money. These spring leaks.

4. Don't proceed without the proper permits or approvals needed.

5. Don't assume that its safe to dig anywhere under a slab on commercial property, Check with power , gas and water plans first.

Materials:

200 ft 1/2 inch copper water pipe - $0.00

200 ft 3/4 inch copper water pipe - $0.00

100 ft 1 1/2 inch Drain PVC - $0.00

100 ft 1 1/4inch Drain PVC - $0.00

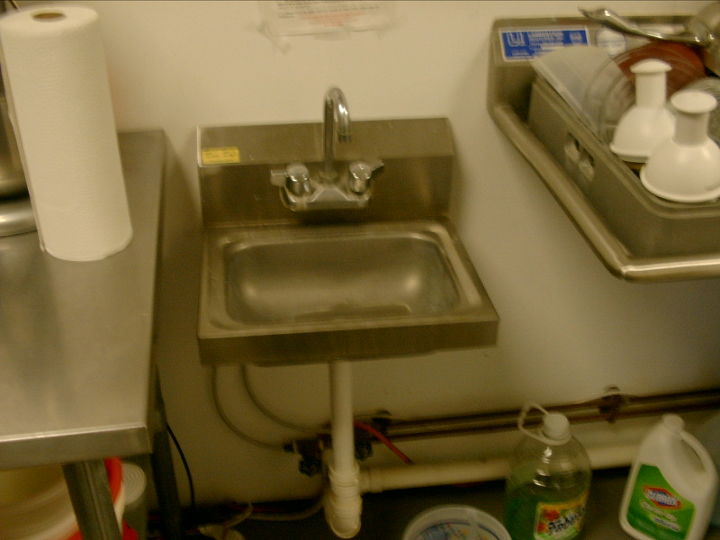

1 Hand Sink - $0.00

80 Gallon Commercial Water Heater - $0.00

Ice Machine - $0.00

Coffee Brewer - $0.00

Espresso Machine - $0.00

Slop Sink - $0.00

Various copper fittings - $0.00

Enjoyed the project?

Published September 8th, 2010 10:17 AM

Comments

Join the conversation

1 comment

-

No Grease trap? That would never fly in NJ. Got to be under every sink, or s there one on the main line before it exits the building? Looks like a nice job. Were waiting for the snow to melt as were doing the mechanicals for a new place called MooYaa some sort of spin off from Dunkin Donuts. And we cannot cut into the six inches of ice on the roof to place the rooftop equipment and exhaust fan systems.

Woodbridge Environmental Tiptophouse.com

on Feb 25, 2014

Woodbridge Environmental Tiptophouse.com

on Feb 25, 2014

-

Frequently asked questions

Have a question about this project?