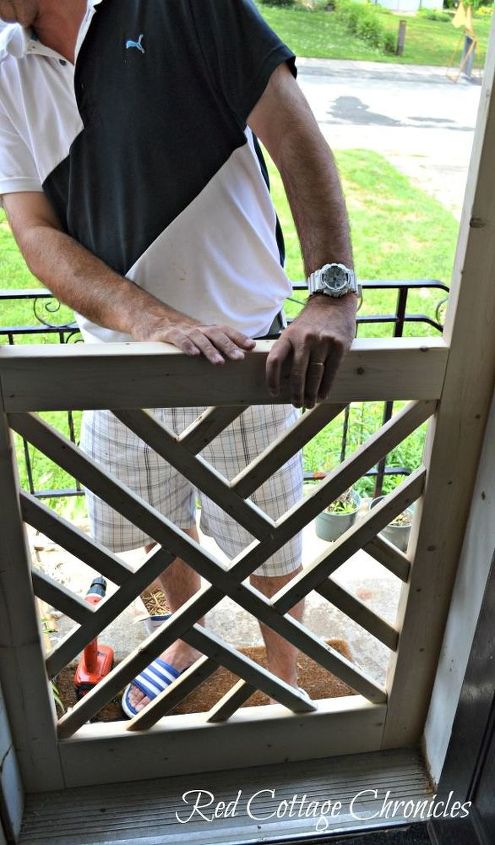

"Chippendale" Wood Screen Door

by

Red Cottage Chronicles

(IC: blogger)

14 Materials

$60

6 Hours

Medium

This wood screen door tutorial can help you save when its' time to replace your screen door. It cost us just around $30 in supplies as we already had a few things on hand, but you could build it for around $60 if you had to buy all the materials.

More often than not we take to DIYing projects out of financial necessity. This new wood screen door is no exception.

Off to Rona to pick up some 2 x 4's, 1 x 2's and a 2 x 6. Choosing very straight boards is essential.

Assemble the frame, ensuring it is square before you fasten it all together using counter sunk 3 inch screws.

Start the pattern by building an X across the lower half with the 1 x 2's. This gives you 4 quadrants to repeat the pattern. We started with the top quadrant and worked counter clockwise.

A 3 inch space between the 1 x 2's ensured an even spacing all the way throughout as we continued to repeat the pattern in each quadrant.

After the second quadrant was finished, the last two zipped along easily and quickly.

And before we knew it, the pattern was finished, and we were dry fitting it to the frame before filling screw holes and giving it a good sanding to prep for painting.

We choose to paint it white, but you could just as easily stain it instead.

You can see the entire tutorial on the blog at www.redcottagechronicles.com as I tried to capture the process as Tim went about his work.

Enjoyed the project?

Want more details about this and other DIY projects? Check out my blog post!

Published August 10th, 2015 6:57 AM

Comments

Join the conversation

2 of 194 comments

-

-

Tobianomama

on Feb 16, 2024

Tobianomama

on Feb 16, 2024

One for the books I am definitely making this one before spring!!

-

Frequently asked questions

Have a question about this project?

Love this but how is the screening secured?

I am unable to locate this screen door DIY project on your blog. Do you have a direct link to it?

Can I please borrow your Mr ? 😊