How to Make a Cutting Board in 30 Minutes

by

American Workshop

(IC: blogger)

$10

30 Minutes

Easy

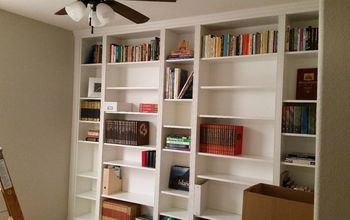

Like most aspiring woodworkers, I love walking into Home Depot and imagining all the things I could make with the pretty, perfect boards I see lining the aisles. But you might be surprised to find out that it only takes a few extra minutes (and almost zero woodworking skill) to turn rough, uneven lumber like this stuff...

...into a beautiful finished product.

The secret is just a couple extra power tools. This is the part where I confess that, even though I work at a public woodshop, I really don't know much about power tools. But when I tell people where I work, the first thing they say is usually, "I would love to get into woodworking, but I wouldn't know where to start!" And I tell them, "Start with a small cutting board!"

The jointer is the first step toward making rough lumber look like that pretty stuff you see at Home Depot. The second step is to smooth out the faces of the board, and to do that, you need a planer.

Once you have the two faces planed smooth, you can run the board through the tablesaw to make the non-jointed edge smooth and perfectly parallel to the jointed edge. And in about 5 minutes, you've got one of those perfect boards, ready to become a cutting board!

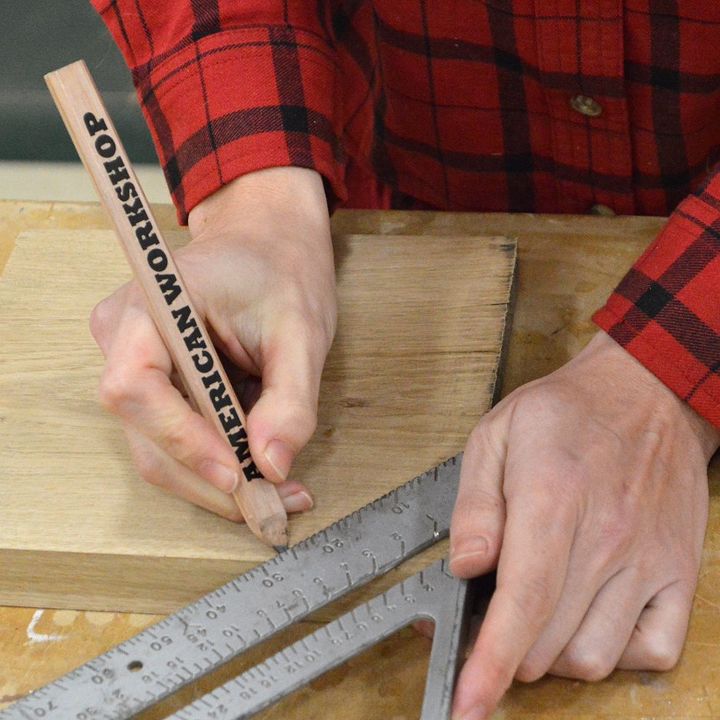

You can make your cutting board any size or shape you want. Just draw your pattern on with a pencil, then head over to the band saw to cut it out.

Of course, your cutting board is going to be so beautiful that you'll want to display it on your kitchen wall instead of hiding it in a cabinet. For that, you'll have to drill a hole so you can hang it. The drill press makes that part super easy.

Finally, for nice clean edges, you can run the cutting board through the router table. You could use a fancy bit for a more elegant edge, but I just used the plain round-over bit that was already in the router. Keeping things simple.

After a final sanding, give your cutting board a coat of butcher block oil to protect it and to bring out the grain.

It may sound like a lot of steps, but you'll be surprised at how quickly you can do it!

Enjoyed the project?

Want more details about this and other DIY projects? Check out my blog post!

Published January 9th, 2016 8:00 AM

Comments

Join the conversation

5 of 23 comments

-

Nice beginner project but unless one has access to a shop equipped with all the power tools required it would be cost prohibitive to buy them, especially for a beginner.

Dan

on Jan 13, 2016

Dan

on Jan 13, 2016

- See 2 previous

-

@Dan You're right! We are an open-to-the-public woodshop: we provide the tools and the space, and you bring your ideas. Our goal is to make woodworking less prohibitive to beginners. :)

American Workshop

on Jan 14, 2016

American Workshop

on Jan 14, 2016

-

with a small sander (or a good strong arm) this could be sanded by hand, it also could be cut with a simple jig saw ( a tool a lot of homes have) plus a hand drill to drill the hole. I started out woodworking with very basic tools and as long as you keep an open mind about things, huge power tools aren't a necessity.

Glenna Kennedy

on Jan 17, 2016

Glenna Kennedy

on Jan 17, 2016

-

-

Frequently asked questions

Have a question about this project?