DIY BBQ / Grill Cart

by

Robin Lewis

(IC: vlogger)

5 Materials

$60

2 Days

Advanced

This is a simple BBQ cart that makes use of dados and rabbets. This is a basic woodworking join where just enough wood is removed so that the joining piece of wood can slot into the gap.

{

"id": "4494159",

"alt": "",

"title": "",

"video_link": "https://www.youtube.com/embed/2IzOpA1b0b4",

"youtube_video_id": "2IzOpA1b0b4"

}

{

"width": 634,

"height": 357,

"showRelated": true

}

For this project I used mostly 1 x 2s, or 19mm x 42mm, pine so it was very inexpensive. The top is made from hardwood decking, it's a timber called merbau.

For the sake of this project I won't go into detail about the top as there are a few ways to go about making this. The easiest way would be to buy a benchtop from a big box store and attach it. It all depends on how big your cart is.

I got into more detail in the video.

The first step is to cut the pieces to length. I wanted my cart roughly the same heigh as the barbecue and about twice as wide.

Next I marked out for the dados and rabbets. I used one of the boards to mark the size of the cut-outs at the ends and in the centre (this'll make more sense in the next step).

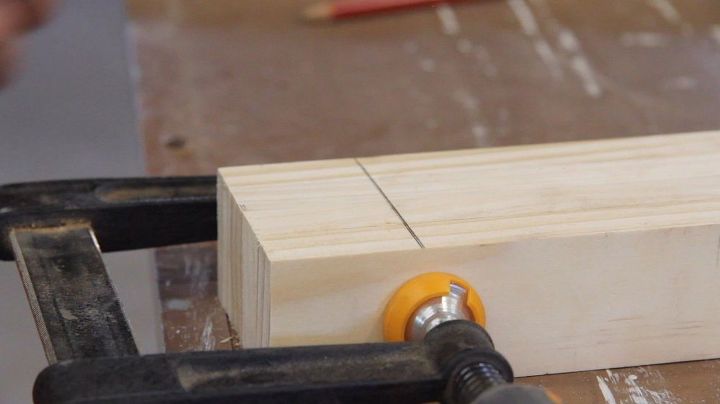

To speed the process up, and give me more surface area to balance the saw on, I clamped as many boards together as I could before making the cut.

I also used one of the boards to mark the depth of the cut. This gave me a mark to line my circular saw blade up with.

Then, using the circular saw and a speed square (to ensure I kept a straight edge) I hogged out all the material. The circular saw got rid of the majority of the material, but I came back afterwards with a chisel and cleaned up the cuts.

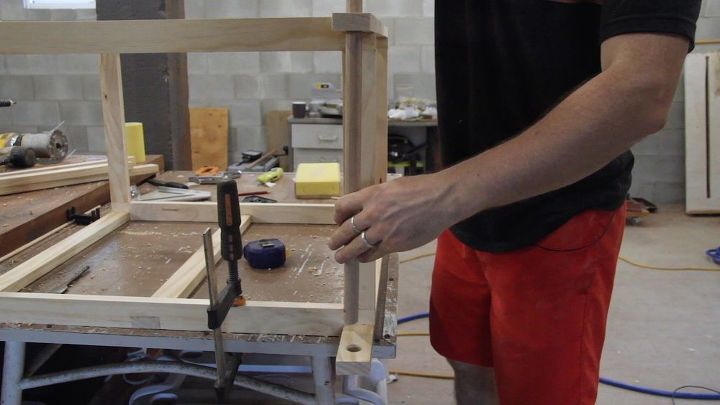

Next, I glued all the parts together using a generous amount of wood glue.

Make sure to coat all the surfaces and check the join for square before clamping.

Once both long rails are glued (see image above) then you can glue the short rails. This join uses end grain so it's very weak. It was only to get the positioning correct.

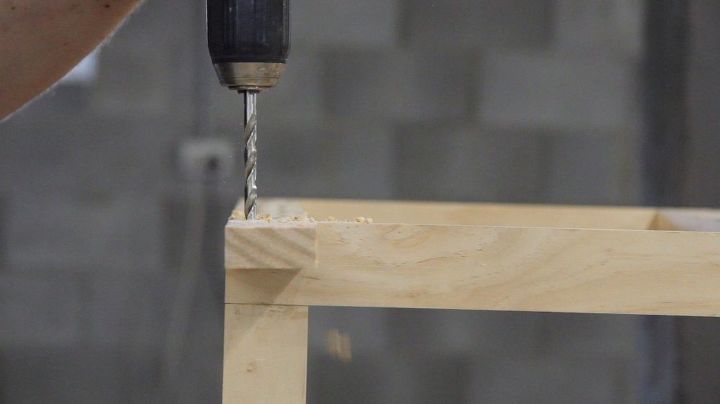

I used a lot of glue and clamped the short rails in place. Once the glue dried i came back with 6mm dowels and inserted 2 into each join.

This way, the dowel run through the join, into the end grain, and provides a long grain to long grain join, which is much stronger.

The dowels are driven in using a mallet (although they shouldn't be too tight) and the excess is cut off using a hand saw.

n the extended end of the long rails I cut a 19mm hole using a hole saw. This would allow for a 19mm dowel to be pushed through. However, before inserting it I drilled a small hole at either end of the dowel so that I could put 6mm dowels into the big dowel.

Then all the parts were sanded and finished. At this stage I cut some 1x2s to be used as slats on the bottom of the cart. Once the finish dried these got screwed in from the underneath.

To attach the top of the cart to the leg assembly I used figure 8 clips.

Lastly I screwed small castors onto the base on one end, and 2 piece of left over 19mm dowel onto the other end. This allowed the cart to be lifted on one end and pushed around.

Enjoyed the project?

Suggested materials:

- Pine 2x4 (Any big box store)

- 19mm dowel (Any big box store)

- Castors (Any big box store)

- Wood glue (Any big box store)

- Varnish (Any big box store)

Published November 26th, 2017 10:25 PM

Frequently asked questions

Have a question about this project?