135 Views

An Assortment of Coffee Tables

by

John Biermacher

(IC: homeowner)

1 Material

$100

2 Weeks

Medium

This posting is a collection of coffee tables I have done over a number of years. For most of them, I only have one photo of each, so I will try to describe the challenges or unique qualities of each table.

The first table is one I built for our personal use over thirty years ago. It was made from a wooden shipping crate. I added the top and the feet. The Hood Rubber Company was a Watertown MA based company started in the late 1800's (http://snaccooperative.org/ark:/99166/w6qs25tv) that manufactured galoshes and rubber boots, not prophylactics. It is still in use in our TV room.

The next table was made just after we moved into a new house (ca. 2007). It was made from two old doors that came out of an old farmhouse near the Michigan/Indiana border that was slated for demolition. They were quite old (pre1900) because they had thru-mortise-tenon joints. The legs and the bottom shelf were both half notched , which increased stability. It was painted black with some edges distressed . This detail will be referenced in the final paragraph.

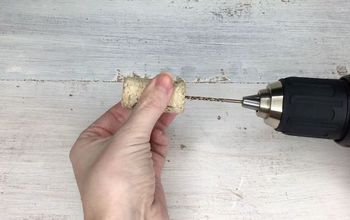

The next table was a display table made from a salvaged window. I did the basic construction for Val, a client and friend. It was for her home and she finished the project. The interesting twist is that we lengthened the legs by adding feet that were old clear glass electrical insulators.

The next table was constructed over the winter of 2017-2018 for a client/friend. Diane and her husband Joe winter in Arizona, so final details had to await their return. The entire table is made out of the remnants of a family piano. The piano had been taken apart years ago, but Diane saved the money pieces- the intricately carved front and the coved key cover.

Even though all the parts came from the piano, it was tricky getting a uniform color and finish on the variety of woods. I was able to match the trim and the base to the top using very light overspray with three different colors of paint. Coating everything with urethane varnish gave everything a constant sheen.

The last table was completed very recently. It is a knock off of a design my wife saw on the internet. The metal supports and legs are angle iron cut from some bed frames I had in my inventory. I relied on a friend (Dave) to cut them using an abrasive saw and another friend (Tom) welded the lower supports to the legs. I had to bolt the upper support to the legs, otherwise there wouldn’t be any way to get the drawer unit in.

The drawer unit and the top are made from 3/4 inch thick birch plywood. Exposed edges with covered with iron-on veneer. The top appears to be thicker than it actually is because I doubled the plywood around the edges, You get the heavier look without the added weight and expense.

This last table has replaced the black “door table” in our family room, mainly because wife got tired of dusting a black table with recessed panels. I can’t fault her, considering that in our 43+ years of marriage I have never dusted anything.

Thanks for viewing.

Enjoyed the project?

Suggested materials:

- Primarily salvaged material

Published July 31st, 2018 11:28 AM

Comments

Join the conversation

2 of 3 comments

-

Diana Holton

on Aug 01, 2018

Diana Holton

on Aug 01, 2018

Tell sue after 43 years of marriage eyesight goes a bit so dusting isn’t important :) you two are wonderful!

-

-

Diana Holton

on Aug 01, 2018

Diana Holton

on Aug 01, 2018

Though it makes me think... I should do a load of laundry or dust ;). I have some nice pieces of furniture:)

-

Frequently asked questions

Have a question about this project?