DIY Rustic Farmhouse Tables

by

Michelle | breakingdownthebox

(IC: instagram)

10 Materials

$75

3 Days

Medium

I am getting thoroughly frustrated with the furniture you can buy in stores. I will pay $200-300 for desks and side tables made of pressed particleboard. Within a year or two, they are already crumbling. On another frustrated note, the designs I like typically end up costing me a lot more than I want to pay, or are missing something! So, I started to learn how to build my own furniture. I typically use less expensive pine you can find in a hardware store to keep the cost down. Any nicks in my kitchen table are considered "memories" - haha! My guests had started asking me where I was buying my furniture - when I told them I actually built it, they were interested in the prospect of me building their own furniture. One of these builds included a coffee table and a pair of side tables for my brother in law's living room. His girlfriend and I did some searching to find exactly what she was looking for and then I came up with a plan and went to Lowe's.

Cut List (for one side table):

- Legs - (8) 2x4 @ 22"

- Connections - (4) - 2x2 @ 16"

- X Design - (2) 2x2 @ 26" long to short, you will want to trace the cut once your legs and connections are assembled. Also, (4) 2x2 @ 13" - again trace this once your longer piece is in place.

- Table Top - (5) 2x6 @ 27"

- Bottom Shelf - (2) 1x12 @ 16"

- Tape measure

- Speed square

- Pencil

- Kreg Jig Pocket Hole System

- Drill and bit set

- Miter Saw

- Sander

- Paintbrush

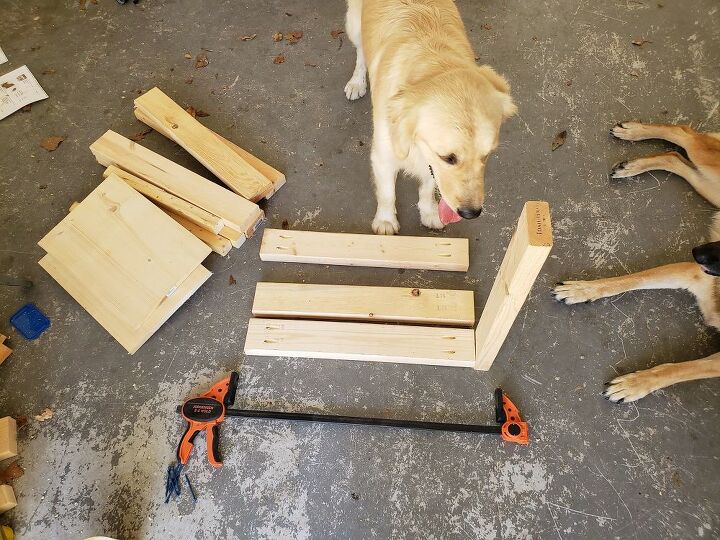

As you can tell, I have a very stressed out helper who is always checking on me during my projects.

Step 2: Connect the sides with the 2x2 connections.

As you assemble the main frame, ensure everything is squaring up nicely.

Step 3: Build your bottom shelf.

Step 4: Attaching the X

Step 6: Build your table top.

Fill in all holes with wood filler and sand smooth!

Step 7: Paint or Stain

For the look I was going for (distressed), I painted a base coat of dark gray.

Then, my other helper assisted with painting the top coat of white.

I stained the table top with Minwax Dark Walnut, wiping it off within the first minute of it going off. When both the base and table top were finished, I attached the table top to the base using normal wood screws. I filled in the holes with wood filler and did a quick touch up with the stain.

Step 8: Distress and Seal

Step 9: Attach leveling feet.

What you end up with is a beautiful, super sturdy and level side table! You can add decorative hardware to spice it up even more, or just leave it rustic looking. They are in LOVE with their set! I loved it so much I wanted to keep it myself -  .

.

.

.

Enjoyed the project?

Resources for this project:

See all materials

Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Hometalk may collect a small share of sales from the links on this page.More info

Published January 14th, 2020 3:30 PM

Comments

Join the conversation

2 of 232 comments

-

Becky at Flipping the Flip

on Jan 19, 2022

Becky at Flipping the Flip

on Jan 19, 2022

Good for you and looks terrific! Your assistants are freakin' adorable!

-

-

Lula Porter

on Feb 18, 2022

Lula Porter

on Feb 18, 2022

LOVE this! The Kreg pocket hole jig changed my crafting! Your style matches my farmhouse, too. And I enjoy working with pine. Now I would cheat on the stamped stuff on the wood. Instead of sanding it down, I would just hide it.

I'm getting back into working with wood and going back to fighting my router. Thank God farmhouse style doesn't have routed edges.

-

Frequently asked questions

Have a question about this project?

They are gorgeous.

I just wonder why everything is labeled.

Rustic Farmhouse design?

These can match just about any Decor with different paints. Thanx for sharing.

Have a safe and Happy New Year

I believe I saw this same size table in Kirkland! Great job!

I love how your pup and daughter are helping you! I wonder if a shelf could be added to the side tables, for extra storage? Very nice work!