What tool would best cut aluminum flashing so as not to curl the edge?

Related Discussions

Blackout curtains behind vertical blinds

I have two 6' patio doors, and I want to add blackout curtains to keep the sun/cold out. What is the best way to hang them, and what can I use to push the curtains ba... See more

How to make a balloon garland?

Does anyone know how to make a balloon garland or a balloon arch?

Does anyone know what this is?

Just turn them upside down and open them, then insert a roll of paper towel and tada, you have yourself a brand new paper towel holder that is not only beautiful, but... See more

Can anyone identify this vintage wooden crank box?

The item is solid wood, standing aprx. 26" high x 16" wide, no exterior holes or outlets, side crank handle turns four wooden paddles inside with various size holes o... See more

What to put in this huge mason jar?

I have a HUGE mason jar. I would like some ideas on what to put in it for decorations, other than flowers.

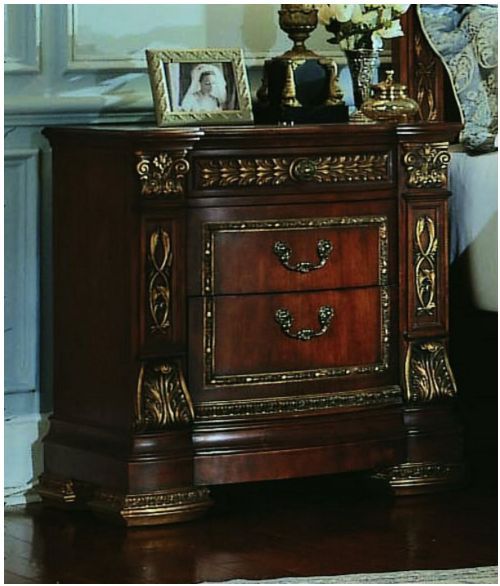

How can I find discontinued Pulaski or Neiman Marcus/Horchow furniture

I am looking for the discontinued Pulaski Royale collection nightstand, Neiman Marcus/Horchow also sold it, but called it the Royalty collection. I have looked all ov... See more

Ideas on different things I can do with these yummy old spools?

I'm a picker and came across lots and lots of these beauties. I took home several boxes of these purdies and are using for different projects. However, I want to find... See more

For thin flashing I use a razor box cutter, score a few times along the cut line, bend up and down along the score line, and it snaps off. Use some sand paper to smooth the edge. For thicker material (aluminum and brass) I use a band saw.

Razor box cutter

Have you actually tried this?

Flashing can be purchased at a sheet metal shop for the length you need as well as the color. They usually supply Home depot and Lowe's so their price would be cheaper. Tin snips works but for big jobs you'll get tired. You can put a grinding wheel on a dremel tool and metal blade for a circle saw . You can also put the curled side under the roof edge. Wish I knew what you wanted it for. What ever you use must be very sharp , unless it's a wheel.

Want to cover outside of kitchen island. It's ugly 7& I want it to look like stainless. Maybe squares with opposing Grains? Just know I need to have smooth edges for gluing down. Not too familiar with DreMel tools but anxious to learn. Maybe all you guys out there can teach me. Who knows, maybe I'll post the project...once I learn hou to cut it.

Thanks for the help.

The metal blade on a circular saw would just tear up the aluminum sheet. I know! A Dremel would take forever and be tough to control to get a straight cut. I use the razor box cutter to cut aluminum sheeting to clad wood window and door frame woodwork.

Thanks all of you! Sounds like razor box cutter will need my weapon of choice.