Don't Lose Hope: Here's How to Remove a Stripped Screw

No matter the quality of your screw or how handy you are at DIY projects, all screws are subject to stripping.

Screws typically get stripped when they have been screwed in and out too much over time or have been continuously overtightened.

Other times, it’s simply improper technique and incorrect tools used when adding a screw or adjusting it that beat it down.

When a screw is stripped, the slots in the head of the screw have worn out, making it seemingly impossible to get it out of wherever it’s stuck.

If you’re dealing with a stripped screw, you’ll need to remove it. The following are different methods to get the job done, in order of what to try first.

While trying these methods, be sure not to force anything if the screw won’t budge. Doing so can further strip the screw or damage the wood around it.

Photo via Shutterstock

Use Pliers

Pliers are usually the most reliable method of removing a stripped screw. If enough of the screw is above the surface, give this method to try. Grip the screw on both sides with pliers (long nose pliers might be best to grab onto the screw), then gently wiggle from right to left until the screw is loosened enough to pull it out.

Switch the Style of Screwdriver

If you’re trying to remove a Phillips head screw from where it’s stuck, applying foreign pressure to the screw may work. Switch to a manual flat-head screwdriver and apply hard pressure to the stripped head at an angle. Carefully try to work the screw out of place—but as we mentioned above, don’t force it or it could strip the screw further.

Photo via Shutterstock

Go Back to Your Drill

If the methods so far haven’t worked, grab your drill to try to get the screw out. The key here is to go very gently so you don’t split or break the screw. At a low speed, drill into the screw with light pressure until you feel traction between the bit and the screw. Once you feel this catch, put your drill in reverse to remove the stripped screw. You can see a video tutorial on how to remove a stripped screw in this way here.

If this doesn't work, try one of the following methods:

Switch Out the Driver Bit

If your screw is slightly stripped but not necessarily stripped clean, you may need to use trial and error to find a driver bit that works. Switch out the driver bit for a bigger one that’s meant to fit a larger head than the stripped screw you’re working with. The larger bit will tackle more surface area of the stripped screw, which translates to more pressure used to help grip onto and remove the screw. Press the driver and new bit into the screw and slowly trigger the driver in a counterclockwise motion to try to remove the screw. If it’s gone a few turns around and is stripping the screw more, stop and try the next method.

Use a Screw Extractor

If the screw doesn’t budge when using a larger driver bit, you may need to use a screw extractor bit in your drill. Screw extractor bits are tools specifically designed to remove broken or stripped screws. Typically, when you buy a pack of screw extractor bits, there will be a few bits in different sizes with double-ended tips (one tip with a looser thread, the other with a tight thread). You want to use the biggest extractor bit that you can fit into the punched slot of the stripped screw and put it in your drill, loose-thread side facing outward. Place the extractor tip in the hole and drill clockwise into the screw to clean out any remaining slot profile, creating a nice smooth hole. Then flip the extractor bit to its tight thread side, put it in the screw’s hole, and drill it out counterclockwise. The screw should come out clean.

Try a Manual Screwdriver

If your drilling efforts have failed, it may be time to go back to manual labor. While a drill takes away the need for putting muscle into the job, sometimes what a stripped screw needs to loosen up is manual control over the torque. Use a screwdriver that matches the stripped screw type. Press in hard to the stripped screw with the screwdriver, then work counterclockwise to pull it out.

Use a Screwdriver and Hammer

If manual effort with a screwdriver alone isn’t cutting it, add in a hammer to create a new slot. This will only work if the metal is soft enough. To do this, stick a flat-head screwdriver into the screw, then use a hammer to gently drive the screwdriver down until it catches. Then twist the screwdriver counterclockwise to remove the screw.

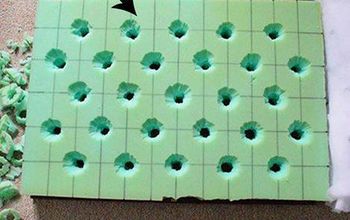

Photo via Barn Tree Place

Find Something to Grip With

Sometimes, it’s just the lack of grip that’s the problem. To better grip onto a stuck and stripped screw, you have a few options. According to the experts at Top Cordless Tools, try to remove the stripped screw by laying a rubber band over the screw head, placing the tip of the screwdriver over the rubber band and into the screw, and turning the driver clockwise until the screw is out. Steel wool is another option. Simply follow the same steps as with the rubber band, but use the steel wool for traction instead.

There are also liquid gripping solutions out there that can help enhance the hold in a stripped screw head. Take DriveGrip, for example. To use, simply squeeze some solution directly onto the screw head. Then try using a screwdriver to take out the screw. The liquid should increase traction against the head of the screw, making it easier to twist out.

Add a Nut

If you’ve tried the above methods to no avail, it’s time to give the screw a whole new head. Keep in mind that welding can be dangerous if performed by someone with experience, so you may have to call in a professional for this one. For this process, find a nut that’s the same size or slightly smaller than the head of the screw and weld it onto the tip of the screw head. Once the weld is set, use a wrench to loosen and remove the stripped screw.

Do you have any additional tips for removing a stripped screw? Share them below!

Frequently asked questions

Have a question about this project?