Installing a Loft Ladder and Hatch

by

The Carpenter's Daughter

(IC: blogger)

$150

6 Hours

Medium

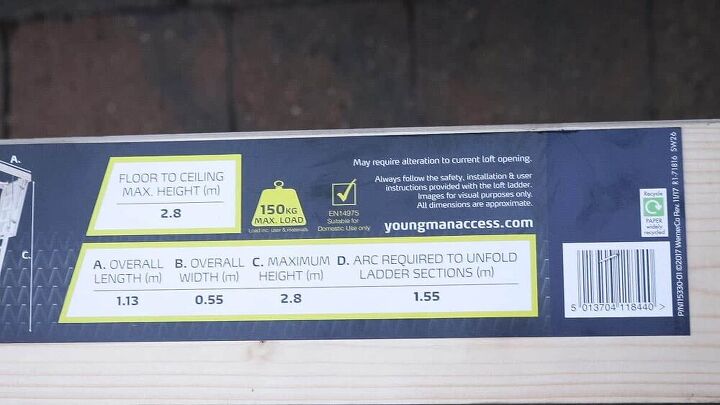

Here's how my Dad and I finished installing a loft ladder with hatch for easy access to the attic, creating more storage space. This loft ladder installation features a Youngman Timberline Loft kit with review, which is unsponsored and unaffiliated. Includes video as a guide.

Disclaimer: I am not a professional and am sharing this DIY loft hatch from a novice's perspective and what I've learnt from my carpenter Dad. Always seek a professional, or loft ladder fitters if you don't know or are unsure of what you are doing.

Tools and Equipment We Used

- Wooden loft ladder without hatch *(requires making a custom loft hatch)

- 2 x plywood gussets (scrap wood, cut into triangular pieces

- Jigsaw

- Hand saw

- Mitre saw *is preferable to make the made to measure loft hatch as it needs to be square

- Tape measure

- Combi drill

- Impact driver

- Reciprocating saw

- Sawhorses

- Clamps or timber to prop up the hatch

- Packers

- Extra structural timber to ensure the hatch is more secure

- Marker pen and pencil

- Architrave trim or UPVC to finish

What Types of Loft Hatch Conversion Kits Can You Buy?

- Sliding loft ladder, available in wood or an aluminum loft ladder

- Concertina loft ladder as opposed to a 2 section

- Timber folding loft ladders with handrail, typically allowing a maximum weight of 150kg

- Insulated loft hatch with ladder (which this Youngman has 26mm of insulation

Youngman Loft Ladder Installation

- Mac Allister

- Keylite

- TB Davies

- Telesteps

- Dolle

- Zarges Loftmaster

- Ramsay loft ladder

- And more

How to Build a Loft Hatch

Cutting the Ceiling For a Loft Hatch

Cutting Through Wooden Beams

Drilling Through the Old Flat Roof

Cutting From Above

Building a Loft Hatch

Tips for Cutting Your Loft Hatch Support

Ensuring You Have a Perfectly Square Loft Hatch

- Measure from each diagonal, corner to corner with a tape measure, to check they are the same measurements. If not, tap the larger corner until they match

- Once square, cut some plywood gussets and temporarily screw to two diagonally opposing corners, so it stays like that. You'll need to remove these later once screwed in situ.

Screwing in the Loft Hatch Support

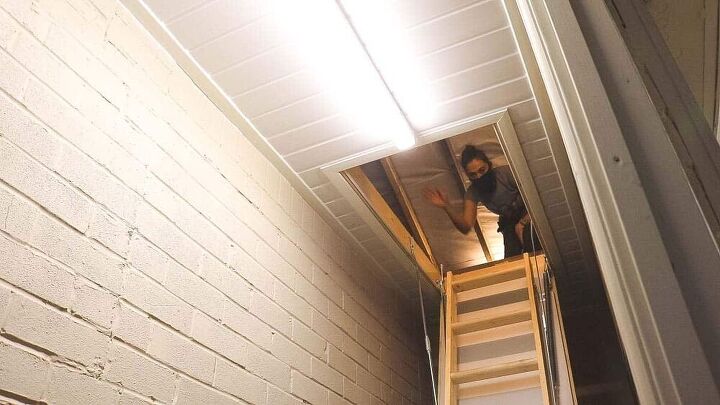

Installing The Youngman Loft Ladder Hatch

Attaching the Hatch Door

These two hanging strips, attached to the hatch's wall then need to be screwed to the bottom of the folding ladder. *But before the fold starts.

Adding The Youngman Loft Ladder Catch

Cutting the Loft Ladders

Cutting the Bottom Folding Loft Ladders

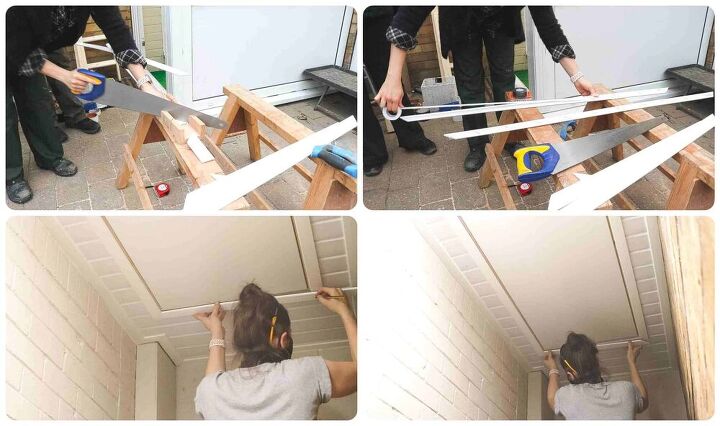

Adding a Hatch Trim to Your Loft Ladders

Using the Youngman Loft Ladder Operating Pole

- We determined and marked where we wanted the loft ladder with hatch to be using a template. *We also made sure we weren't cutting through pipes and cables and replaced any structural timber supports.

- After drawing around the template, I drilled a hole to slot the jigsaw through and cut the UPVC cladding.

- When hitting wood, we used a handsaw to cut through timber.

- Once the fascia was removed, I we then used a reciprocating saw to cut the majority of the timber.

- I then drilled a hole in each corner and poked scrap plastic in each as a reference for where to cut from above.

- Then cut with the reciprocating saw again, but this time, from above and removed that section of roof.

- Next, I cut and screwed a structural frame around the loft kit insert, then removed the insert.

- We then took the loft hatch frame to where we'd cut and trimmed any protrusions before making even, resting above the fascia.

- Using packers, we screwed the frame to the roof beams with several 4 inch screws.

- Next, we took the loft insertm with the protruding hinges at the back, facing upwards and made flush with the fabric, then screwed to the frame.

- Then hung the hatch door and fitted the ladders to the them as per the manufacturer's instructions.

- As the ladders were too long, we opened them out, while the folded area was aiming backwards and measured the distance from the floor to the fold and cut the bottom piece to the same length and screwed back.

- Finally, I cut some UPVC beading for trim with a mitre box and stuck them around the cut edges of the opening and rang along the outsides with silicone.

Enjoyed the project?

Want more details about this and other DIY projects? Check out my blog post!

Published March 1st, 2021 12:29 PM

Comments

Join the conversation

1 comment

Frequently asked questions

Have a question about this project?