DIY Bacon Soap

by

Rebecca D. Dillon

(IC: blogger)

8 Materials

2 Hours

Medium

This DIY Bacon Soap makes a great homemade gift idea for men - and women! - who love bacon. It's also a great way to let Dad know that you love him on Father's Day. Made using real bacon (rendered) fat - save that bacon grease! - this DIY bacon soap yields nine hard, extra conditioning homemade soap bars perfect for the shower! Leave your soaps unscented or scent this DIY bacon soap with your fragrance oil of choice.

Things to note. While this DIY bacon soap is made with bacon, it does not smell like bacon. If you'd like a bacon scent you can find a bacon scented fragrance oil online from a variety of soapmaking suppliers.

You'll need to begin by rendering your bacon fat. Basically all this means is you'll need to cook up a bunch of bacon and save the grease that's left at the end. I saved up my bacon grease over many weekend morning breakfasts in cups in the fridge. Once you have the necessary amount you can either strain out the tiny bits of bacon that may have snuck in or leave them in just for fun. (I totally left mine in. No, they will not go rancid.)

My homemade bacon soaps were ready to unmold the next day. However if you live in a particularly humid area you may want to wait an additional day before unmolding to ensure your soaps come out of the molds cleanly.

Enjoyed the project?

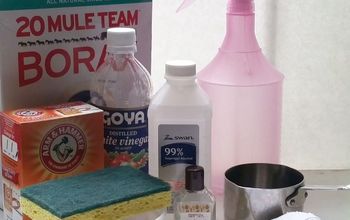

Suggested materials:

- 8.75 oz. bacon fat, rendered

- 5 oz. 76 melt point refined coconut oil

- 3.75 oz. castor oil

- 7.5 oz. pomace olive oil

- 8.25 fluid oz. distilled water

- 3.5 oz. sodium hydroxide/lye

- 1.5 oz. fragrance oil, optional

- Two Wilton 6-Cavity Silicone Heart Molds

Want more details about this and other DIY projects? Check out my blog post!

Published June 12th, 2016 12:14 PM

Comments

Join the conversation

4 of 9 comments

-

Sylvia Laura Ranyak

on May 06, 2021

Sylvia Laura Ranyak

on May 06, 2021

I am a true bacon Person, I don’t think I would make this because I would be afraid some animal would want to take a bite out of me. 🤣.

-

-

Sylvia Laura Ranyak

on May 06, 2021

Sylvia Laura Ranyak

on May 06, 2021

Good to know, I will try it.

thanks for letting me know and thanks for sharing with us.

-

Rebecca D. Dillon

on May 24, 2021

Rebecca D. Dillon

on May 24, 2021

You're welcome!

-

-

Frequently asked questions

Have a question about this project?

Is this why children eat tide pods?