Pallet and Staging Plank Workstation

by

Rob & Courtney M, Hometalk Team

(IC: paid contributor)

20 Materials

$60-75

2 Days

Advanced

Hey guys! Rob here! In our house we work with the space that we have. Our living room is also Court's office/studio, so I made her a tall desk out of a metal frame and an old door last year -- she also has a bookshelf that's packed out, a side table that is filled, 3 Rubbermaid cabinets and 2 Rubbermaid storage bins. Needless to say, Court has needed an additional work station for a little while now, so I came up with a design that is multi-functional and gives her extra storage.

Because I sort of jumped into work on this project, I didn't get a chance to take a supply photo so here is a list of the supplies I used:

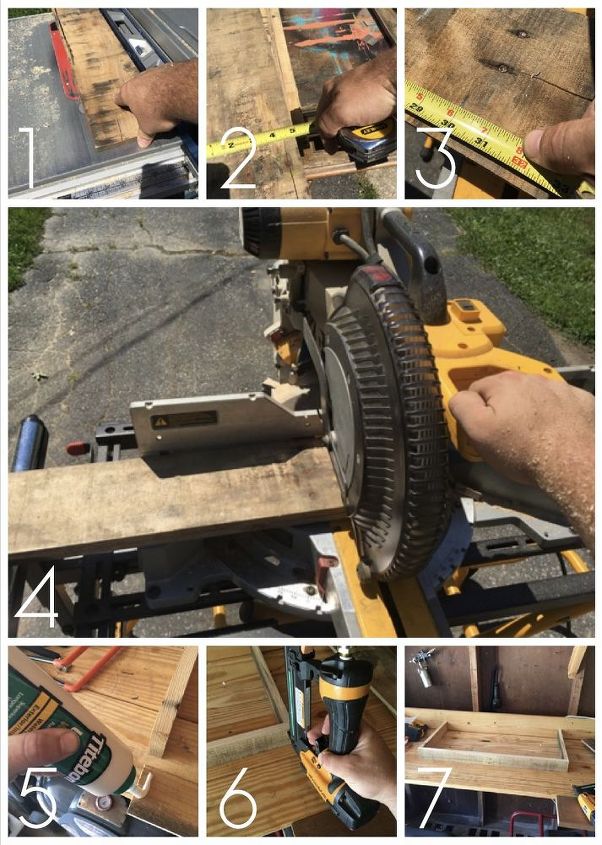

STEP 1: Make the shelves

Next, I fastened the shelves to the frames also using wood glue and trim nails. In total I made 6 shelves.

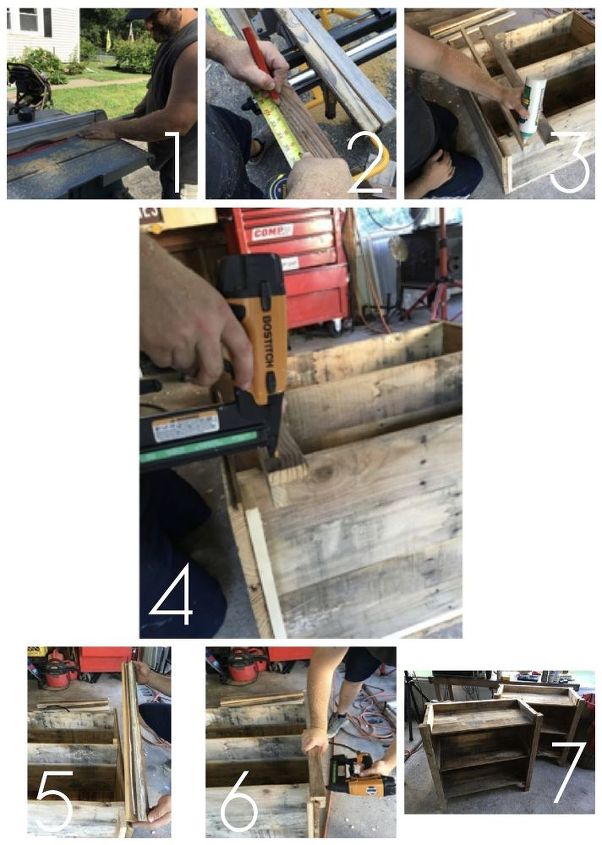

STEP 2: Assemble shelves into bookcases

(Photos 1-4) Once I had all of my wood cut it was time to assemble the shelves. I started by laying two shelves on the ground and clamping a piece of beadboard to them to hold it together. Then, I laid out the remainder of the board I would need to make up that side. I scribed the last board and ripped it on a table saw to make it the right width.

(Photos 1-4) Next, I laid the bookcase face down and marked where I wanted to middle shelf to sit. Then I glued the sides of the shelf, slid it into the bookcase, and nailed it in place.

(Photos 1-4) Then I made legs for the bookcase using a 2” rip and a 1 ¼” rip, both cut to 32”. I assembled them together for a “corner” using glue and nails.

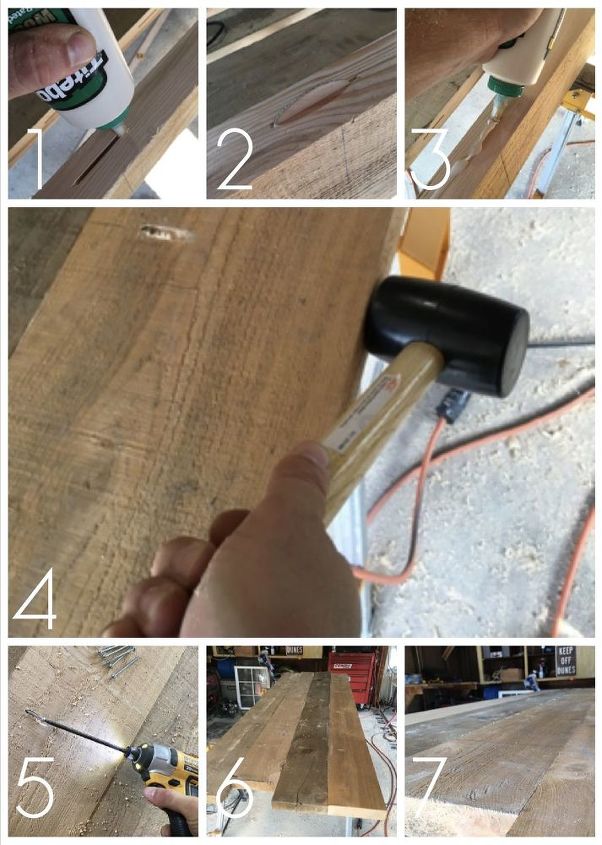

STEP 3: Make the tabletop

Typically I would just glue the edges of the boards and clamp them together at this point to make the table top which would require letting everything set up overnight while the glue cures. Since I am in a time crunch and need to finish the same day, the following steps were added to keep the project moving along. I ended up using a biscuit joiner and pockethole screw to hold the work together.

Then, I put glue in each slot and inserted the biscuits. Once the biscuits were inserted, it was time to glue the edge of the board.

Once I had completed my joinery, I cut the ends of the table top.

STEP 4: Finish the tabletop

NOW THE FUN PART!

Court absolutely loves her new work station! She did all of the painting on the bookshelves using samples of Behr exterior flat acrylic paint -- her method was doing a quick whitewash-method where she lightly coated the beadboard on the outside of the bookshelves, then once dry, quickly and lightly sanded, then applied a thin coat of Minwax paste finishing wax using an old rag. She did the corners and shelves with a vintage white.

Enjoyed the project?

Suggested materials:

- Pallet boards (18) (on hand)

- Staging planks (4) (local building supply store)

- Miter saw (on hand)

- Table saw (on hand)

- Wood glue (Home Depot)

- Trim nails (Home Depot)

- Beadboard (on hand)

- Measuring tape (on hand)

- Clamps (on hand)

- Biscuit joiner/biscuits (Home Depot)

- Rubber mallet (Home Depot)

- Pocket screws (Home Depot)

- Palm sander/sandpaper (on hand)

- Torch (on hand)

- Brush sander (or grill/wire brush) (on hand)

- Satin Polycrylic (Home Depot)

- Behr exterior flat acrylic paint (Home Depot)

- Minwax paste finishing wax (Home Depot)

- Paint brushes (Home Depot)

- Old rag (home)

Published July 31st, 2016 9:16 PM

Comments

Join the conversation

4 of 20 comments

-

Cool looking desk!!

Tiena Nobles

on Aug 23, 2016

Tiena Nobles

on Aug 23, 2016

-

-

What is a "Staging Plank?" I have been in woodworking for 55 years and the only thing close was a Ginger Bread Cookie with pink frosting. They used to sell them at country stores. Other than that I never heard of the term.

Terry Tyson

on Aug 28, 2016

Terry Tyson

on Aug 28, 2016

-

In the carpentry industry, they are also referred to as scaffold planks--the name is interchangeable.

Rob & Courtney M, Hometalk Team

on Aug 29, 2016

Rob & Courtney M, Hometalk Team

on Aug 29, 2016

-

-

Frequently asked questions

Have a question about this project?