Beach Inspired River Table With Sand Dollars - GLOWS in the DARK

In this Hometalk post, I show you step by step how to make a live edge resin river glow table. This beach inspired table closely resembles the Emerald Coast water color in Destin Florida and has many awesome features.

The live edge river table top is made with cypress wood with a light tone and rests on custom made hairpin legs. The live edge cypress leads down to an epoxy resin river that runs through the length of the table.

The bottom epoxy resin layer of the river table contains green phosphorescent pigment (glow powder) followed by a layer of sand and sand dollars.

Phosphorescent pigment powder shines through the sand and sand dollars with a subtle glow, which resembles the beauty of the Destin, Florida beaches.

Gather Materials & Mill Wood

To start, I begin all of my projects by gathering the correct materials. This live edge epoxy resin river glow table is no different.

I realize this may seem simple, but it is definitely not. In fact, it is the hardest part of the project for me because it requires me to step through the entire project from start to finish.

Also, I listed all tools and materials I used for this project at the top of this post.

Live Edge Cypress Wood

I have a locally owned Cypress sawmill not too far from where I live in Louisiana.

During one of my visits to pickup cypress for a different project, he gave me a raw piece of new growth cypress. I liked the light color, grain pattern, and the fact I could build a really awesome live edge river table.

Mill Wood

To achieve great results with any woodworking project, I believe it is vital to use wood with straight sides, square ends, and a flat surface. Ultimately, it reduces frustration and makes the project so much easier.

First, I used my Japanese hand saw to cut off the end of the Cypress. The live edge cypress did not have a straight side to rest against my miter saw fence. Therefore, it was unsafe to cut with anything but a hand saw.

Next, I used my festool track saw to rip the wood down the middle with 2 passes rather than all at once. Again, the wood did not have a straight side so the table saw was not an option. Additionally, I find myself using my table saw less and less now that I have this Festool track saw.

Then, I ran the live edge cypress through my surface planer to get each side flat. Luckily, the cypress had one flat face even though it still needed to be sanded. So, I was able to get the other face flat by referencing the face which was already flat.

Finally, I used my miter saw to cut one end of the wood at 48". Next, I flipped the wood over and cut the other side at 45". Remember, one side of the wood has a live edge which cannot be placed against the fence of the miter saw. So, I had to rotate the the wood and flip it to ensure the flat side stayed against the fence.

Remove Loose Debris

First, I used my Festool RO125 sander to clean up the live edge side of the cypress.

Next, I used my wood carving tools to remove the loose debris for 2 shallow wood cavities. I vacuumed the cavities to make certain they were clean.

Prepare Resin Mold

I used a thin piece (1/8") of dry erase board large enough to fit the live edge river glow table. I presume this is melamine, but not entirely sure.

First, I wiped furniture wax on the surface to ensure the resin would not adhere to it. Also, I've heard vaseline works just as well as furniture wax.

Next. I placed the wood on the melamine with the live edge facing inwards. Using my combination square, I made sure each piece of wood was pushed in 3" from the melamine.

Ultimately, this step saved me an additional step later in the project of squaring the sides of the table. Since each side was cut with my track saw, I knew they were perfectly. So, no need to get them straight again.

Then, I used a scrap piece of wood with F-clamps to secure the wood to the melamine. I used silicone caulk to seal the inside of the live edge river to prevent resin from seeping through.

Also, hot glue works just as well as silicone.

Resin Mold Ends

After I finished securing and sealing the river table sides, it was time to complete the mold by adding the two ends.

First, I cut 2 pieces of wood the larger than the width of the river. I covered them with packing tape and wax.

The exact length doesn't matter as long as it is wider than the river.

Next, I used my brad nailer with 18 gauge 1.5" brad nails to secure them.

I used brad nails because they are quick and the holes are easy to cover up when nailed into end grain. Hot glue is a good alternative to brad nails.

Then, I sealed each end with silicone to prevent the resin from leaking.

First Epoxy Resin Pour with Glow Powder

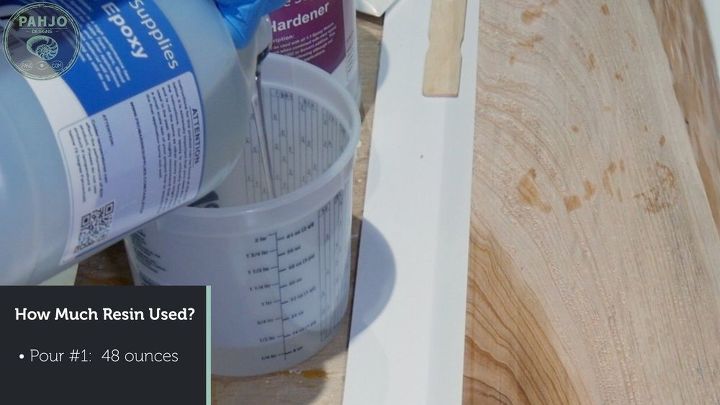

The first epoxy resin pour consisted of 48 ounces of resin and 4 ounces of glow powder.

First, mix 48 ounces of resin in a 1:1 ratio.

Quick Tip: Epoxy Resin Ratio Accuracy

It is vital to mix epoxy resin at an exact 1:1 ratio. So, I use the inside measurements on the container when pouring epoxy resin. Ultimately, it is easier to see and more comfortable to use during the epoxy resin pour.

Once the ratio is correct, I began mixing the epoxy resin with a paint stick.

To properly mix epoxy resin, I stirred slowly in a circular pattern. Also, I scraped the sides and bottom to make certain everything was mixed evenly.

Normally, I use a pattern while mixing: 3 side circles, 3 bottom scrapes, 3 inner circles, and repeat over and over again.

After the epoxy resin was properly mixed, I tested the glow powder to verify the color with a black light.

Next, I added 4 ounces of green glow powder (phosphorescent pigment powder) to 48 ounces of resin to this live edge resin river glow table. Art n Glow recommends using a 4:1 ratio of resin to glow powder; however, I feel this is a bit overkill for my river table projects. So, I use a 12:1 ratio of resin to glow powder and this works fine.

Once the glow powder and resin were mixed thoroughly, I poured the resin in the river table.

As I poured the resin, I moved back and forth to each end of the table.

Next, I used my torch to remove bubbles.

Add Sand to Bottom

After the first layer of epoxy resin cured for 24 hours, I added pool sand.

First, I sprinkled enough pool sand to lightly cover the top.

Next, I moved the sand around with my finger tips into an acceptable pattern. As you will learn in the next step, the pattern didn't matter.

Second Epoxy Resin Pour

I mixed 48 ounces of resin and mixed per the instructions. Once the resin was completely mixed, I added 1 drop of transparent blue dye.

Next, I poured the resin slowly in the live edge river glow table. As you can see, the resin pushed the sand to the side.

Then, I used my ruler to spread the sand evenly on the bottom of the live edge river table.

Additionally, the ruler helped me create a natural pattern with the sand similar to the ocean floor. I made certain the sand was thin enough for the glow powder to shine through.

Place Sand Dollars

After I spread the sand, I placed the sand dollars in the live edge river table.

First, I used my paint stick to push the sand dollars to the bottom in a random pattern. Luckily, the sand helped create somewhat of a suction.

As I pushed the sand dollars down, a small amount of sand came through the holes in the sand dollars. This created a very natural look that was completely unintentional - I love when that happens. :)

Third, Fourth, & Fifth Epoxy Resin Pours

After the resin was completely cured (24 hours) from the second pour, I lightly hand sanded the epoxy resin river with 220 grit sandpaper and proceeded with the third pour.

I mixed 48 ounces of resin with 1 drop of transparent blue dye.

I poured the resin from one side of the table and allowed it to flow evenly to the other side. I used my heat gun to move the resin around and my torch to remove the bubbles.

As a quick tip, I like using my heat gun when I pour a large amount of resin. I find it helps move the resin around and force bubbles below the surface to the top.

Fourth Epoxy Resin Pour to Fill Cavities

Immediately after the third epoxy resin pour, I filled the wood cavities in the live edge river glow table.

I mixed 12 ounces of epoxy resin.

Next, I added one ounce of pearl white pigment powder and one ounce of white glow powder to the resin.

After I mixed the pigment powder and glow powder, I carefully filled the wood cavities with a popsicle stick while preventing the resin from dripping into the resin river glow table.

Despite my best effort to not spill any resin, a tiny bit dripped into the river. No harm, no foul as it was barely visible.

Then, I removed the bubbles with my torch and added more to ensure the cavities were completely filled.

Fifth Epoxy Resin Pour

After the resin cured for 24 hours, it was time for the fifth pour.

First, I lightly hand sanded the river with 220 grit sandpaper and removed the dust.

Next, I mixed 48 ounces of resin and 1 drop of transparent blue dye.

Then, I poured the resin in the river glow table just like the previous step.

Sixth and Seventh Epoxy Resin Pours

After the resin cured for 24 hours, it was time for the final pour.

I estimated the river glow table only needed 24 additional ounces to reach the top of the table. So, I mixed 24 ounces with 1 drop of transparent dye and poured the resin.

Shortly after the resin pour, I realized I needed 24 more ounces. So, I mixed 24 more ounces just like before and poured the resin. Thankfully, this did the trick!

Remove Resin Mold

I allowed the live edge resin river glow table to cure for 48 hours before I removed the silicone mold.

48 hours seems like a long time especially when I am excited about a project; however, I learned the hard way many times 48 hours is necessary.

Honestly, I was hoping for a clean sweep with no resin leakage. Unfortunately, this didn't happen. The resin leaked through the wood cavities which explains why I had to fill it multiple times.

Overall, not a bad outcome at all.

I packed up the table, the majority of my tools, and began the 3 hour drive to our house in Florida for the summer to finish it there.

Table Bottom Clean Up

The first thing I did in Florida was remove the silicone caulk and the pieces of melamine that stuck to the bottom of the live edge river table.

First, I used a utility knife and gently cut one side of the caulk at a 45 degree angle. I repeated this on the other side of the same bead of caulk.

Next, I simply peeled the caulk away from the table.

Then, I used my Festool RO125 with 180 grit sandpaper to remove the melamine. I use the highest grit possible to remove clean the bottom of my tables to save time.

Finally, I used 220 grit sandpaper to finish off the table bottom.

Match Water Color Attempt

Forgot to mention that my attempt to match the water color was pretty close. ;) .

What do you think about my attempt?

Sanding

Now to the boring, but most important, part of my river glow table project - sanding.

First, I decided to use 4 sanding grits: 120 grit, 180 grit, 220 grit, and 320 grit. I started with 120 grit sandpaper because the table was relatively smooth from my new planer knives. Normally, I start with 80 grit sandpaper.

Next, I worked my way through the grits making sure to sand with the grain of the wood in a slow, steady pace.

After I finished with 320 grit, I wiped the table down with a damp rag to raise the grain.

Then, I sanded the live edge resin river glow table again with 320 grit.

The top coat I chose to finish my table with was a water based satin product by general finishes.

Ultimately, I decided to use this finish because I love the light color of this wood and prefer the matte/flat look.

First, I applied a thin layer with a foam brush. I let this dry completely and then sanded with 320 grit sandpaper using my orbital sander.

Next, I applied a second coat in the same manner then sanded with 320 grit sandpaper by hand.

Finally, my daughter and I applied the final coat.

After the table dried, I installed black UV LED lights on the underside of the table.

This was not necessary, but I like to do this in order to charge the glow powder if the table is placed where natural light is not available. Additionally, the table glows brighter with the lights on and some people like this.

First, I measured the length I needed.

Next, I cut the black light strip in the correct location to ensure the lights will work. The lights normally have a dotted line with a scissor emblem to mark where to cut.

Then, I used super glue to secure the black led lights to the underside of the table.

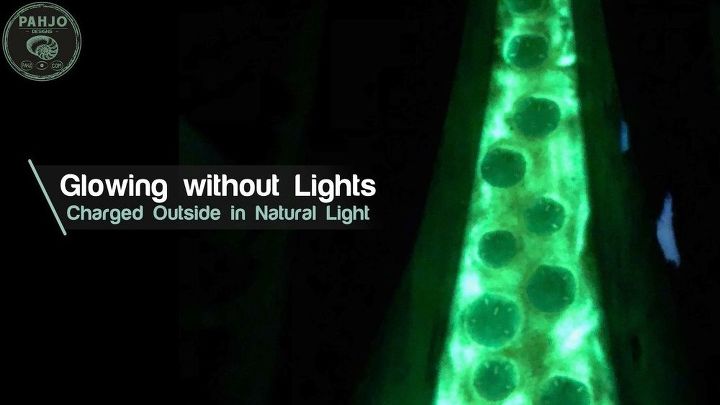

Glow in the Dark Table Details

After taking the final pictures in the natural sunlight, I glanced at the table and realized it was glowing brightly. So, I closed the curtains and turned off the lights to get a better picture.

This picture is after 3 hours of bringing the table inside.

I kept the live edge river glow table in the dark until the glow powder lost it's charge, which was the following day.

Next, I brought the table in a room with very low light and charged the glow powder with the black UV LED lights.

While this charged the glow powder quickly, the glow coverage was not as consistent. It would work much better if the black LED light strip was covered on the underside of the table. This would allow the black UV LED light to reflect off the material used to cover it, which would result in more parts of the river glow table to get charged.

Conclusion

In conclusion, I hope you learned how to make a beach inspired live edge resin river glow table and this project brought you some form of value.

Please consider and visiting my website for more projects and other fun stuff. If you want to build a table like this, I have detailed digital plans available for download that walk you through entire process step by step.

Feel free to contact me anytime if you have any questions. I'm happy to help!

Enjoyed the project?

Resources for this project:

See all materials

Frequently asked questions

Have a question about this project?

Could you lay glass over the top once you are done and it has dried? ?

I used resin for a bar top and back bar that were made from an old dresser and chest of drawers. Repurposed project.

The product indicated that, over time the finished product will “move” in a self leveling sort of way.

Did you use a resin that will not “move” over time for example that would change the open edge of you river table?

Where do I purchase the sand dollars.