Wanting to know how to make ur own knotty pine hardwood flooring.

-

Try researching Duragrove.com installation, familyhabdyman.com or I found theres a video on u tube.

Janet Pizaro

on Sep 25, 2015

Helpful Reply

Janet Pizaro

on Sep 25, 2015

Helpful Reply -

-

I'm assuming that you are asking what you need to make the lumber tong and groove? If so, you'll need a router, a table for it and tong and groove bits that will work for the thickness of the wood you'll be using.

Z

on Sep 25, 2015

Helpful Reply

Z

on Sep 25, 2015

Helpful Reply -

-

Here's a few more ideas I was able to find for you. http://www.diynetwork.com/how-to/skills-and-know-how/carpentry-and-woodworking/how-to-cut-tongue-and-groove-joints You can also do them on a table saw, which I have personally done before, but it takes more time. I was only doing a small job so time wasn't a problem. I figured I'd go ahead and share just in case that's how you want to do yours. http://www.woodworkersjournal.com/cutting-tongue-groove-joints-table-saw/

Z

on Sep 25, 2015

Helpful Reply

Z

on Sep 25, 2015

Helpful Reply -

-

I kept looking and found an "almost" excellent visual on how to use a table saw to make the tong and groove. He forgot to add that the when making the groove you need to turn the piece around to do the cut from both sides of the wood to get the thickness you need. You'll noticed he switched view in the middle of the cut where he started doing the first and ended showing the second cut, but didn't mention he'd turned the wood. https://www.youtube.com/watch?v=kei_h3rYv9E

Z

on Sep 25, 2015

Helpful Reply

Z

on Sep 25, 2015

Helpful Reply -

-

You can make it with a tablesaw. I've made my own pine tongue and groove, not for flooring but for the back of cabinets.

Follow your H

on Sep 26, 2015

Helpful Reply

Follow your H

on Sep 26, 2015

Helpful Reply -

-

Christina, I am just finishing up my own knotty pine kitchen floor. I've collected the lumber pieces from all over: reuse centers, packing crates, pallets, etc. anywhere from a 16" wide piece to beautiful bug-kill 6" pieces, but mostly anything with interesting grain or knots. I didn't even try to tongue and groove it. Reused and self-milled wood can be tough. I beveled the edges. I didn't want a crack between them to show up in the colder weather, so I overlaid it. I did face nail with a 2" finishing nail. They're virtually invisible, which pleased me to no end. I might actually decoratively "peg" them -- or not. I'm loving the way they've turned out and am very, very pleased with the bevel.

Christine

on Sep 27, 2015

Helpful Reply

Christine

on Sep 27, 2015

Helpful Reply -

-

Here are some of my boards down, squirted with water to show the grain. Oh - good news. Pine is soft. Before you sand or do any finishing, squirt the whole thing down. Any dents from installation, dropped hand tools (don't ask me how I know) etc., will pop back up as long as the dent doesn't cut the wood. I keep moving my fridge which makes bad sliding marks. Squirt. All gone!

Christine

on Sep 27, 2015

Christine

on Sep 27, 2015

Helpful Reply

Helpful Reply -

-

I hope it lasts, Christine, because in my house the wood would shrink and grow depending on the humidity. Our humidity is not constant. If yours is, you may be okay. The tongues and grooves are to allow for changes in the width of the wood.

Follow your H

on Sep 28, 2015

Helpful Reply

Follow your H

on Sep 28, 2015

Helpful Reply -

-

We found a post by another HomeTalk user that shared how she made her wood floors. You can find the info at the end of this post: http://goo.gl/ZULyTz

HouseLogic.com

on Sep 30, 2015

Helpful Reply

HouseLogic.com

on Sep 30, 2015

Helpful Reply -

Related Discussions

Chair rail height?? At the sill or below or around?

I am running chair rail around a bedroom. The marble sill is 40" from the floor the window is 39" high. Putting printable wallpaper on the bottom. Painting the botto... See more

Best nail gun?

I am very new to working with tools and am wondering what the best type of nail gun I should buy to work with pallets. I am interested in redoing a wall with pallets ... See more

How can I seal old chipped wood?

I have a few amazing pieces that are old and the paint is chipping. I love them just the way they are but hate the flakes that constantly come off! What to do so it'... See more

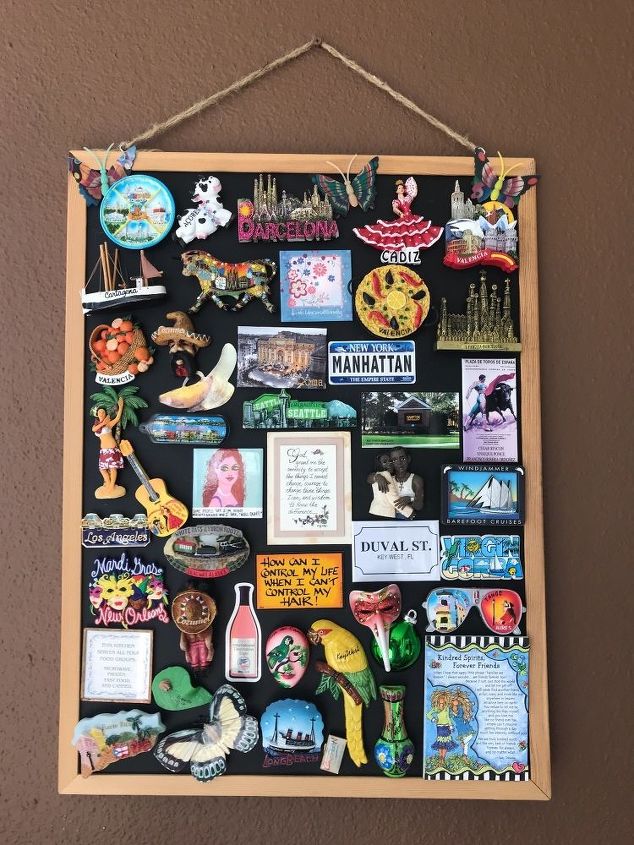

How to make a magnetic picture board to display (travel) magnets.

Cutting a wooden spool

Can anyone suggest the best way to cut a wooden spool in half length wise. Approx. 16 "tall, ends are wood and the center is thick. I have several different power saw... See more