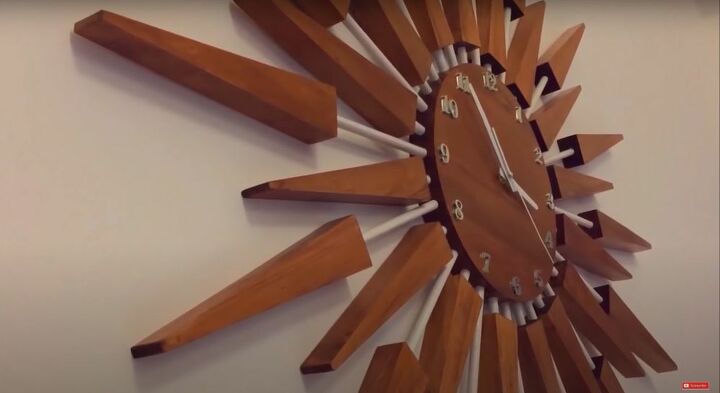

Learn How to Make a Classic Mid-Century Modern Sunburst Clock

I had been looking for the perfect clock for a while. I wanted something that would be clean and simple, but still make a statement. This mid-century modern sunburst clock was the perfect answer to what I had been looking for. It utilizes scrap wood and doesn’t cost a lot at all. You probably already have most of what you need for it lying around your house, and whatever you don’t have isn’t hard to find. Follow this step-by-step guide to help you make your own!

Tools and Materials:

- Ruler

- Card stock

- Pencil

- Wood - I used scrap wood for mine, but in general you’ll need one square piece, to cut the center circle out of, and a board large enough for 32 rays to be cut from

- Circular Saw

- Electric sander

- Wood glue

- Jigsaw

- Electric drill

- Router

- Stain

- Clear lacquer

- White paint

- Paintbrush

- Four wooden dowels

- Quick dry glue

- Mallet

- Clock hardware

- Clock numbers

- 3 escutcheon plates

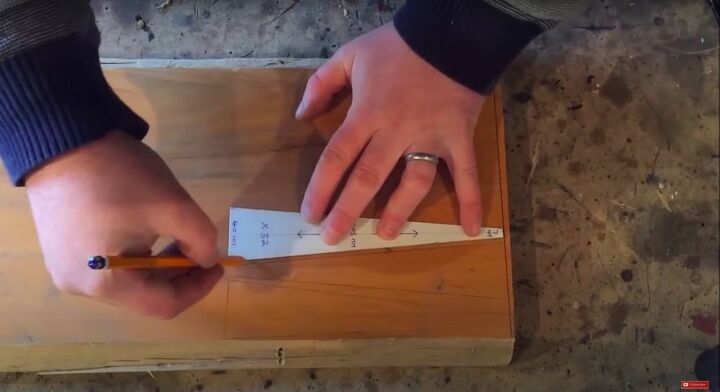

To get started, I created a template for the rays. This can vary for you, depending on how big you want your clock to be, but the basic idea is a long isosceles triangle, with a flattened end at the top point. I would be tracing it quite a few times, so I drew my template on a piece of card stock. Card stock will hold up better to repeated use than a regular piece of paper.

I used some scrap wood that I had lying around for the rays. I took the template I had created and traced out 32 “rays” for my clock.

You can save on waste by doing them facing alternate directions.

Then I cut the pieces out using a circular saw. Using a circular saw allowed me to easily control where the saw went, and I was able to make precise cuts. The first time around I clamped the piece to my work table. For the second round of triangles I chose to screw the piece of wood into my table. When making this yourself, do what works best for you.

As you can see, I cut through the triangle, but didn’t match up the ends, keeping the piece I”m cutting still attached to the rest of the board.

Then, once I was done, I made one cut across the top, creating the cut off triangle ends that I had drawn in my template.

With my triangles cut out, I sanded each side of every triangle. This was a lot of sanding, so I suggest you use an electric sander to cut down on time and effort. I flipped an electric sander on its back and clamped it to the table. Then I ran each side of the square along it.

I was trying to use up some scrap wood, but I didn’t have a square piece big enough for the center of the sunburst. I took two pieces and glued them together, creating a square.

I clamped them together until dry to make sure that they wouldn’t come apart.

Then I quickly sanded it before moving on to shaping it.

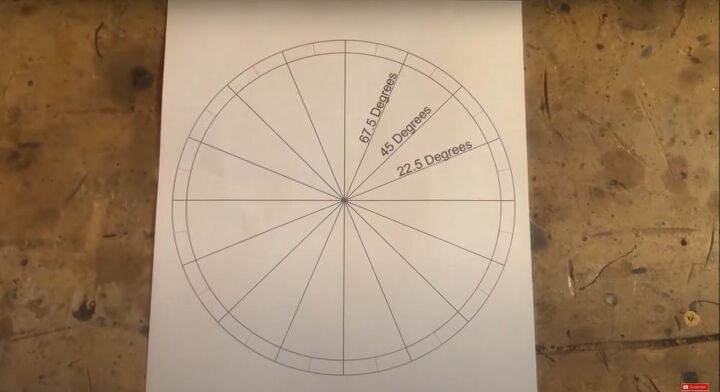

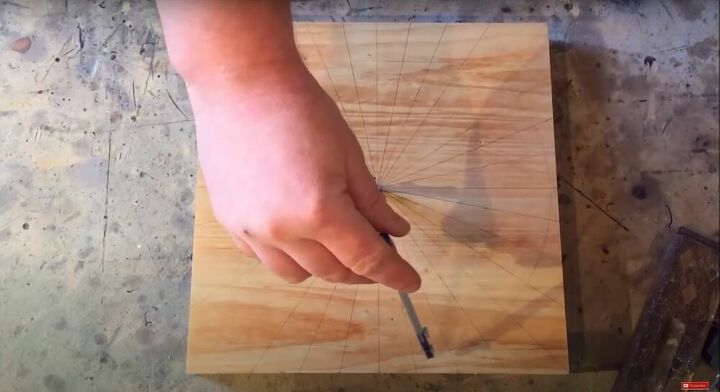

Then I created a template for how I wanted the rays to be laid out.

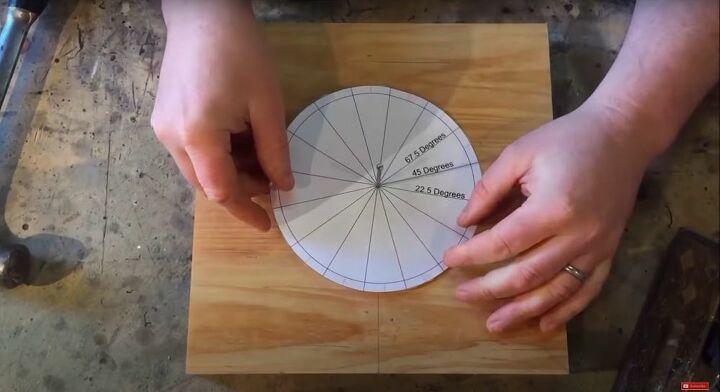

I cut out the template and traced it onto the center of my block of wood. This would serve as a guide for where to put the wooden dowels attaching the rays to the center of the sunburst. Don’t worry about any of these lines showing, this will eventually be the back of the clock.

Then I used a compass to create a perfect circle.

With the template traced onto the wooden square, I took a jigsaw and cut a circle to serve as the clock face.

Then I sanded along the side of the circle. For this, I laid an electric sander on its side and slowly sanded along the edge of the circle.

I needed to create a way to drill the holes at an even height within the clock face. To do this, I lay my drill on its side and screwed a board to my worktable to raise the clock face to the right height. Using the lines I had drawn on the back of the clock face as a guide, I drilled holes for the rays. When doing this, make sure that the holes that you drill are slightly bigger than the dowels, big enough to accept them but not so big that they end up sitting loosely.

With the holes drilled into the clock face, it was time to drill matching holes in the rays. I didn’t want to have to measure and find the center of the end of each ray, so I found a different way to make sure I drilled holes exactly in the center. Using the board I had already screwed onto my worktable, I marked the edges of the fat end of the ray with pencil onto the board, and placed the drill directly in the center. Now I could easily center each ray and drill the hole, without needing to measure each time.

Using the hardware as a guide, I created holes with a router for the clock mechanism and for the escutcheon plates. Make sure to drill deep enough to properly install them, but not so deep that you go through to the other side. It’s also imperative that you do this on the back of the circle, where you had made your markings for the rays. I also took this opportunity to install the escutcheon plates.

With all of my wood pieces cut and sanded, I moved on to staining. I used a rosewood dye to stain my clock. This color is a perfect representation of the mid-century modern style. Due to all of the surface area, it did take a bit of time to stain every piece on every side, but I love how it turned out.

To save on time, and get an easy, even coat, I used a spray lacquer to seal everything. Make sure to allow time for all of the rays to dry, and then flip and seal the other side.

I chose to paint the dowels because I wanted to give a bit of a contrast to the clock face and rays. I used a basic white gloss paint, and then propped them up to dry on the scraps I had from cutting out the clock face.

With the dowels dry, I cut them to size for the rays. I wanted the rays to be at two different lengths, so I cut 16 pieces at 3”, and 16 pieces at 7.5”. Remember that a good chunk of the dowel will be inside the clock face and rays, so don’t forget to take that into account when you measure for your own piece.

Using a quick dry glue. I glued each of the dowels in place on the clock face.

I alternated long and short pieces, using a mallet to make sure that it was pushed in to the end.

I put a dollop of glue in the hole in the ray, and then secured it onto the dowel. It’s important to do some of the shorter rays before attaching the longer rays between them, because the longer rays will make it more difficult for you to fit the shorter rays in afterwards.

I used self adhesive clock numbers. This made it easier to apply, and I didn’t have to worry about any glue showing on the clock face if I accidentally put too much. I first applied the 12, 3, 6, and 9 to make sure that I had them evenly spaced. Then I added the rest of the numbers. If you want to go for a clean look, you can use only the quarter hour numbers, or even use no numbers at all.

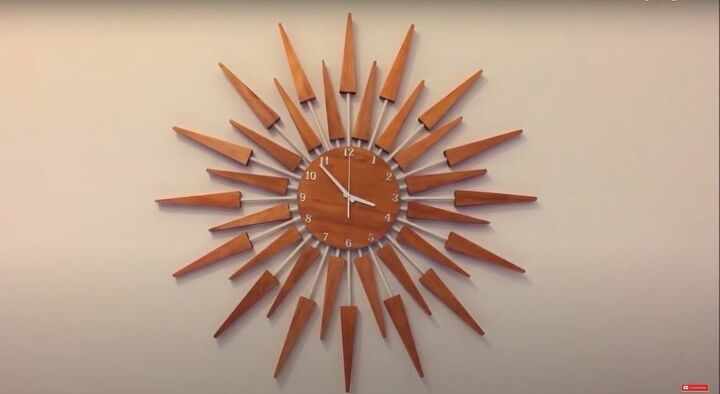

The last step was to add the clock hardware. It’s easy to find different clock mechanisms and hands to fit your style online. Wanting to stick with my color scheme, I found one that had silver and white pieces. The white tied into the dowels, and the silver fit the numbers.

Isn’t it stunning? I love how this sunburst clock turned out. It is clean and timeless, the perfect mid-century modern piece for your home. Have you given my project a try? Let me know in the comments below!

Frequently asked questions

Have a question about this project?

Any chance you can share a more detailed picture and explanation of how you secured your sander (and drill!) on its side. It never occurred to me to try such a thing. How did you stabilize it securely? I see a clamp in the picture, but did you use just one? What kind of clamp? Your clock project is absolutely gorgeous, and I would love to try replicating it. Thank you for sharing!

I would like to know the dimensions of your clock. Diameter of center, length and size of dowel rods size of sunbursts. Thanks