How can I replace the crumbled weight base of my torchiere lamp?

Related Discussions

How to get rid of mice?

We seem to have some unwelcome Mickeys and Minnies in our house. What is the best way to get rid of them?

How to remove popcorn ceiling with asbestos?

I want to remove my popcorn ceiling, but it has asbestos in it. How do I go about this safely?

How to caulk baseboard gaps?

How do I fill gaps at baseboard, should I caulk? If so, does anyone know how to caulk baseboards?

How to fix squeaky hardwood floors?

How do I fix squeaky hardwood floors?

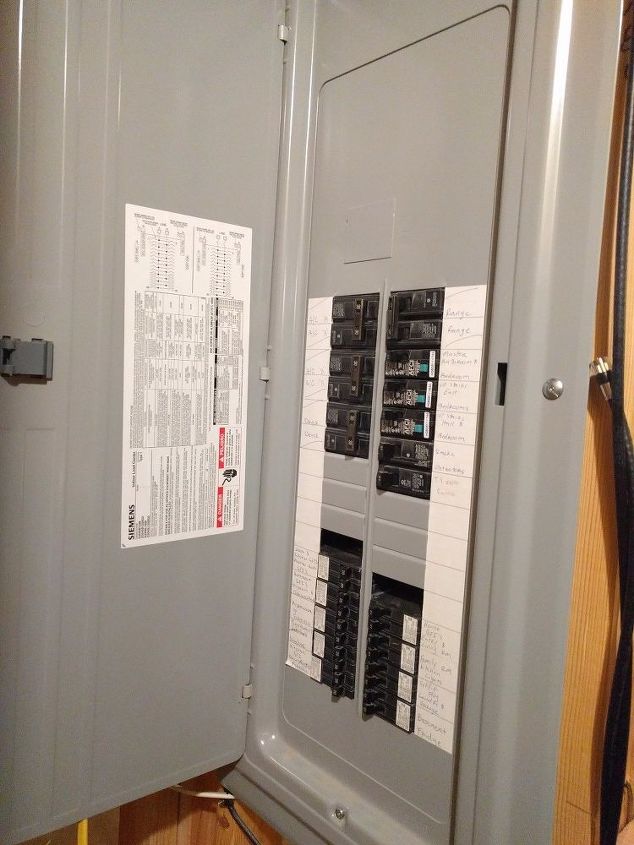

How do I kill the power from my main breaker?

I have a home built in 2006, the main panel does not seem to have a main breaker...? See attached pic of the main panel. It's a Siemens G3040 200 amp panel. Outs... See more

Any Ideas for this corner with the wood stove pipe?

I am unclear as to what to do with this part of my house, "The Breakfast Nook".

I fixed mine by attaching a 5 lb barbell weight to the bottom in place of the original base

I got a table lamp kind thing, but this is close to 7 feet and same as you I broke the bottom plaster too . I am thinking of getting a round plate (exercise weights) 15 or 20 pounder that whose circumference is not bigger than the lamp base and fix it with not and bolt same as how the plaster was.. if the hole in the middle of the plate is big then put a big washer and fix the nut.. hope it helps you

Cheers,

Arjun

So is consensus, plaster will not be heavy enough on its own? I am going to put 4" PVC over inner opening, in underside of metal base. To make room for working the nut back on to the lap pole rod. Then fill it up with plaster or whatever. The metal base is 5 " deep. Still thinking through, what to use to make it heavier. On a continued note-the concrete inner base covered in hard plastic coating, just disintegrated, plastic also. Can break with your hands. Must be the lye in concrete. Also need to make sure metal base strong enough to hold weight of lamp straight. The original plastic covered concrete had a plastic bracket to bolt the rod to.

I used a bar bell weight with plastic feet bolted in, I drilled 4 holes from the top down and used big washers to bolt it in with nylock nuts then repainted the base flat black, the bolts are not really noticeable

backerboard - It weighs the same as concrete because it is concrete (without the rocks). Backerboard has a re-bar like (fiberglass) mesh reinforcement so it doesn't crumble. It is easy to carve as 40 year old set concrete (not). I use a concrete drill to rough out the shape, then a hammer, chisel, jigsaw, and a collection of blades to break through the fiberglass. It takes a lot of patience and a good collection of swear words.