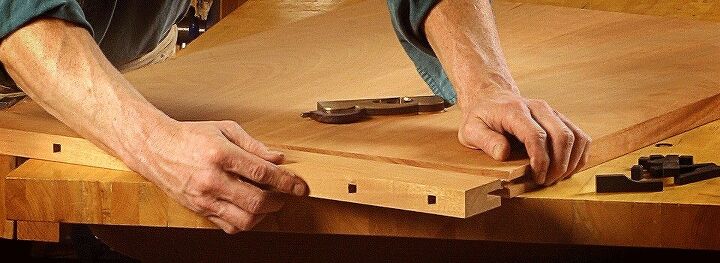

What Do You Know About Woodworking?

Related Discussions

Review: Command Hooks Are Life Savers! What Do You Use Them For?

I LOVE these little life savers. I'm a renter so I always have to find that balance between making my space mine and making my landlady angry.That's why I'm crazy abo... See more

Southern Traditions: Why Did My Grandmas Sweep Their Yards?

My question as I watched these grandparents was always, "Why are you sweeping your yards, and why is there no grass around your house?" We have grass around ours.

What Are Some Unexpected Uses for Dryer Sheets?

I looove using dryer to sheets to make my cloths smell great, and I know that they have a bunch of other surprising, helpful uses as well. What are some unexpected wa... See more

Help me overcome my fear of drills!

I'm getting a drill for as a birthday present I'm really excited, but I'm also concerned. I have a bit of a fear of power tools.What are your best safety tips for han... See more

Can you help us coordinate our TV stand with existing End Tables?

A TV stand is not available in the style of our end tables. It has been recommended to us that we look for a TV stand that is in contrast to the two tables (photos p... See more

Cleaning TIPS Challenge!!!

We challenge you to share your favorite Cleaning Tips with the Hometalk Community for the chance to win a a fun prize!!(Start a discussion with your entry- http://www... See more

Sandpaper can be your best friend! Followed up by a good paint primer (Zinsser) and good paint brushes-Purdy. Great supplies can be purchased at Lowe's or Home Depot. Read about your project on the internet and try Yu Tube instructional videos for more detailed information. Also "Measure twice --cut once" as the very famous quote goes!

advise for a beginner. read instructions on line. And Keep your fingers away from the saw

Start with projects that have a good chance of success. It is far better to succeed making simple, modest pieces than to get overwhelmed, frustrated and disappointed because you bit off more than you could chew with an elaborate project. Start small around the house: Kill two birds with one stone and learn while you take on a smaller fix at home. Fix your porch, build a doghouse, make your own birdhouses, refurbish a piece of furniture, etc. To be successful at this craft, you need to be as knowledgeable and skilled at choosing wood, preparing it, and accommodating its peculiarities as you are at working it with tools. Your work will be no better than the materials you choose and your understanding of them. Unlike metal, glass or clay, wood is a product of biology and therefore extremely varied. Each species, each tree and each board is different — and the differences matter. Of course, this is part of wood's wonderful appeal, but it does create considerable demands on the woodworker. Like most crafts, woodworking requires a substantial infrastructure of tools. This can be intimidating and costly for a beginner, but it's also very tempting as you browse catalogs while anticipating shiny new tools. Remember: tools are for making things, not for mere acquisition. I suggest this sequence: Decide what you want to build, anticipate the steps required to build these pieces, then get the tools to perform those tasks excellently and efficiently. Avoid false economy — buy high-quality tools even if that means having fewer tools, deferring a purchase or spending more. Also, it is better to choose a top-quality, versatile tool than a highly specialized gadget, especially one that is purported to require little skill. Start with a table, clamps, some chisels, hammer, orbital sander, cordless drill, measuring tools, sandpaper, glue, safety glasses, and hearing protection. Focus on hand saws, jigsaws, and circular saws as they’re the cheapest and should work for 90% of your home projects. Never forget how dangerous a power tool can be, always do your research before using a tool you are not familiar with. Read the manual, do a dry run with the tool unplugged to familiarize yourself with how the tool works. Add tools as you need them. Softwoods such as pine or spruce are good woods to practice with, when you become more confident move on to the more exotic woods. Making shop fixtures and jigs is a great way to hone your skills, many of them can be made from used, scrap, or recycled material. I could go on but it would probably take up this whole site!

I've taught woodworking at a University. It's my favorite pursuit. The previous suggestions are sound. Simple joinery frequently works as well as complex joinery, so keep it simple. Wood is fairly forgiving, but don't use dull tools, or cheap machines, which often have more play, and thus are less precise. Do your homework, if buying tools. Read product reviews from woodworking sites, like Fine Woodworking. Rust is not your friend, so keep machines in good shape. Don't trust working drawings in magazines. They can be off in their measurements, review those, and then measure twice, and cut once, as the old adage goes. Always check your set-ups with scrap wood, first. Never attempt to cut or drill wood at a bench, without using clamps that won't slip. If stock, like plywood, tends to splinter at cutting or drilling edges, back the wood for your project up with scrap wood on the splintering side. Don't go against the grain if you don't have to, when cutting anything. If routing by hand, work from left to right, and back to front. If routing with a router table, work from right to left, and never between the fence and the bit. If planing boards, always shoot the wood across the knives with the grain going upward, not downward. If using a jointer to surface warped wood, choose the convex side as the side to machine, and drop the wood onto the knifes partway along the wood, or you can end up with significant taper, and ruin your stock. If you have a planer, always shoot the wood across it with the grain pointing down, not up, since the blades cut from above, the reverse of jointers. Never attempt to cut more than 1/16 of an inch off at a time, with either machine. That can cause rip-out, is harder to control, and it's hard on motors. Always use hearing protection and safety glasses. Be aware that sound can richochet in a small shop, amplifying decibels. Take your time and always, always, keep your fingers out of line with blades. If you're tired or start making mistakes, walk away and leave the project for another day. I could go on about tools. Table saws are great, but bandsaws have a lot of versatility, and are my favorite machine. They can do many of the same things a table saw does. If you have a radial arm saw, you have to slow the feed down, holding back, or the blade can run away with you. Those, and shapers, are the most dangerous machines in a shop. Bandsaws are the safest. But no machine is completely foolproof. The best advise I can give you is to approach any project when you're rested, and be alert. Listen as well as look, since if you're running into trouble, the sounds you're hearing can alert you to it.

A little more jointer wisdom: if you intend to glue panels together to make wider surfaces, when doing edge jointing, line up the boards so that the ones that will be glued together alternate sides, with the intended top side of one board against the fence, and the intended bottom side of the next board against the fence: Top, bottom, top, bottom, etc. Make pencil mark arrows on your edge grain, before jointing, showing which face will be against the fence. These should alternate, for adjacent boards. Any variation from true squareness between the fence and the table will be compensated for, when the glue-up's done, by doing this. It's wise not to attempt to glue together wide panels, since, especially in flat sawn wood, the planks will tend to warp, in the direction opposite that of the annual growth rings. Alternating the direction of those annual growth rings, up-down-up-down, when viewed from the edges, helps prevent this, but won't stop it completely. Rift sawn wood works a bit better, since there's less of a curve to the end grain. Quarter sawn wood is least likely to warp. Its end grain shows mostly parallel lines, through the plank, not along its width, but through its thickness. Good luck finding any quarter-sawn wood, though. It's rare.

Patience is the first thing to learn. There have been people who have built whole homes and castles with a pocket knife or minimal tools. Home Depot and Lowe's offer free weekend classed. Go, even if it is just a bird house. Each class is different. Then decide what you want to build, because if it is fine furniture, you'll need a lot of tools and skills. Your work shop can cost from $20,000 up depending if you are start with the shop and the electrical already installed. Other wise a table saw, a circle, good drill, jigsaw and a hammer are good starts. You will need some clamps and different size levels, these you can use to help cut a straight line by clamping the level down for a guide with an allowance for the distance of the blade to the desired cut. Which brings you to saw horses. You tube will become your friend. Good luck and hang in there, it is addicting.

All of the above have stated some very good advice, but I don't think I saw-(no pun intended !), anyone mention the moisture content of the wood your working with, and for that matter the temperature of your work shop/ work area! Even for finding that garage sale item you plan to restore, sometimes--many times the item or materials you purchase have been in non-heated warehouses or a garage with no heat. Everything can be going well with your project until you move it into a warm living environment, then comes the heart break of shrinkage, checking, and splitting. Acclimation of your item or materials to the temperatures their going to be exposed to is pretty important, particularly in cold and damp climates! The Oregon climate--Willamette valley is not a woodworkers best friend!

count your fingers before and after your project.

do not wear gloves while working with electric saws.

If you are a novice I recommend investing in a jig saw and a circular saw first. Once you feel comfortable with these (a drill has to already be something you are used to with various bits) you can move on to other more specialized tools. All of these are available at Walmart, Lowes, etc.

All this advice is great and Home depot and Lowes have work shop on weekends. Check them out. The best Idea I have though is get some feathers to trade Norm Abram's for his shop. LOL

Working in my shop this weekend, it occurred to me that is all this advice you are getting, things are getting left out. Attacking wood working in like learning to do your own tune ups on your car. Changing a tire is easy if you have done it a lot but your first time can be very difficult and dangerous. But a circle saw is a not a tool for a beginner. Have some one that has been around any of these tools show you what you can do and not do. If the words "kick back" don't mean anything to you, think seriously about being with an experienced person or in a great medical insurance company. There are so many little things, wearing a dust mask when sanding a lot, safety glasses, hearing protection, the dust and mess that comes with this. Never, ever become complaisant with these tools, they are like a pet rattle snake, they will kill you if you turn your back. I apologize for not taking this more serious. It is a wonderful and self satisfying hobby or job. Jig saws and drills are nice starters, but when you buy anything read all the instructions and look at some videos on You Tube for that tool. Smashing your finger with a hammer is nothing like cutting it off. Think about what everyone tells you thoroughly.

In many of the larger communities, people who share a common interest get together in groups or associations, to pursue that particular passion....quilting, wood carving, photography, etc. In my area, the community college offers classes for beginning woodworkers; perhaps something similar is available near you. Although they no longer offer them, the High Schools here had Adult Education classes which offered many different classes, woodworking among them. I learned to crochet, and have made several rugs because of a class I attended thru the Adult Education class on the subject. I also attended the woodworking classes several times, because they were taught at the High School, which afforded me the ability to use their equipment without having to purchase them. Many of those tools cost into the thousands of dollars. Although Home Depot and Lowes offer classes, you might inquire if there are any known groups which are for those people who are just learning woodworking. I wish you good luck.............woodworking is a wonderful hobby that one can enjoy their entire life.