DIY Saddle Seat Bar Stool

We built our island over a year ago and we either don'e use it or we stand or sit at it awkwardly, until now! I finally decided to build some stools (because apparently i'm too cheap to just go buy some!). I'd have to say that they are the thing I am most proud of that I have ever made :)

In this tutorial I'm going to show you how to make a super sturdy, affordable, and beautiful stool for your island. This stool will be able to be passed down generations because of its fine craftsmanship!

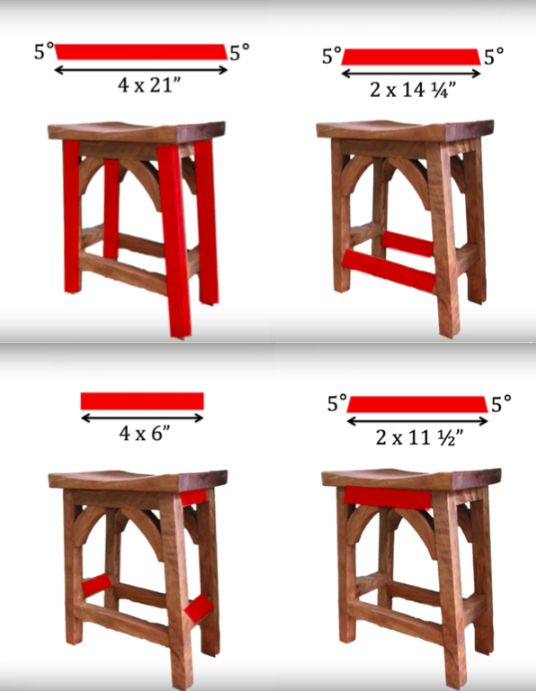

STEP 1: CUT PIECES

The first thing we’re going to do is cut all of the pieces for the base and seat of our stool (with the exception of the arced pieces). I used 2x2 beech for this whole project. Rather than buying 2x2s though, I used 1x10’s since that’s what I had and then I just cut them to my desired width so I had nice clean edges (unlike store-bought 2x2s that have rounded edges).

My legs were cut at 21” with a 5 degree angle on both ends.The bottom cross bars were cut at 14 1/4” and the top ones are 11 1/2” with 5 degree angles on both ends, with the angles going in towards each other unlike the 4 legs)The shorter crossbars were all cut at 6” and do not have angled ends.

STEP 2: SEAT

For my seat I used 7 2x2s cut at 17”. I drew out a template for the groove in my sattle seat (which you can find here). I cut one using the band saw and then traced it onto the rest of the pieces, making sure to rotate my pieces to the side so that my grain remains as is once they are cut.

Once I figured out the best way to arrange them, I glued them together, brushing glue on both adjoining sides. Then I clamped them together, placing two clamps on the bottom and one on the top to help prevent bowing.

Once it was dry, I sanded it down. I started with a grinding disk to get rid of all the ridges and then finished it with an orbital sander with 120 and then 150 grit sanding pads.

I scraped the glue off the bottom and sanded it with a belt sander using course grit paper.

Once I got the seat sanded down I used my table saw to trim the edges.Once everything was straight and smooth I routed the edges using a quarter round router bit and then gave it one more final sand.

STEP 3: LEGS PART 1

Then I started working on my legs. I started by making the front pieces and a matching back piece.

I arranged the pieces where I wanted them, measuring (4 inches??) from the bottom and keeping the top pieces flush with the top of the legs.

Then I marked a straight line at each intersection so I knew which angle my dowels needed to go at since some of them will have to be on 5’ angles.

I chose to assemble my stool using 1” dowelling, but you could use dominos, screws, or joinery (???) to assemble all the pieces. I cut my 1” dowel in 2” pieces, so each of my dowel holes needs to be 1” in depth and 1” wide.

For the long legs, I cut a small piece of wood, that would angle the wood 5 degrees horizontally so that my dowel hole would go in at the proper angle. The piece of wood is flat on one side and cut at 5 degrees on the other.

I used a 1” forester bit for this part.

For the cross bars, I cut another small piece of wood, that would angle the wood 5 degrees vertically so that my dowel hole would go in straight.

Measuring needs to be very precise for the dowel holes so that you don’t end up in trouble later like I did. Keep in mind that your front and back pieces and all of their holes need to be identical in order for your stool to be square.

I used Lepage wood glue to assemble and then clamped them together. Since I was trying to clamp 5 degree angles, I cut little blocks that were 5 degrees on one side to make it more square and easier to clamp.Once it was dry, I scraped off the glue with a chisel.

STEP 4: LEGS PART 2

Now its time for the short pieces that attach the front and back legs.The two pieces on the bottom are slightly different than the two pieces on the top.All of the pieces are placed flat in the vice but I used a 1/2 bit and 1/2” dowel for the top pieces since it will be intersecting with the dowel previous used for assembly.

I realized that these top pieces also need to be cut at a 5 degree angle on the long side in oder for it to sit flush with the other pieces. To do this, I simply tuned the blade on my table saw to 5 degrees and ran my pieces through.

For the bottom pieces, I used the one inch forstner bit again.

After my front and back legs were fully dried (since I’m drilling into another dowel), I drilled a coordinating 1/2 hole in the top corners, making sure they lined up perfectly with the dowel holes.

Then I gave the whole thing another sand.

Now for the arched accents. These pieces are just optional flare.

I drew on my design (which you can find a link to here) and cut it out using the band saw.

I marked where each piece fit best, glued them, and clamped them in place.

For extra support you could put a 1/2” dowel on either end of the arch.

STEP 5: ASSEMBLY

Now its time for final assembly. Make sure you do a final dry fit (no glue). Then I recommend marking exactly what piece and what dowel goes where, because some pieces may fit slightly better in one spot than another and you don’t want to find that out once you’ve already started gluing.

STEP 6: FINAL GLUE UP

If some of your dowels are tight or need some encouragement, you can use a mallet and a scrap piece if wood as to not damage your stool to bang it into place!

Once you’ve got it glued up, clamp it and leave it to dry.

Once its try, chisel off any excess glue and give it one more final sand.

To attach your legs to your seat, I drilled 4 holes, followed by a counter sink hole and then used 2x8 wood screws.

STEP 7: STAIN

I used a wood conditioner to prevent blotchiness and then stained it using early American stain by Minwax.

Frequently asked questions

Have a question about this project?

Can I download the plans?