DIY Leather Magazine Holder

Disclosure: This post was written in collaboration with Fiskars. All opinions are my own.

With all that’s been going on in the world, we’ve been intentional about carving out time to create projects and try new things. Not only does it help keep our creative juices flowing, but there’s such joy to be found in building something with your own two hands.

For this project, we wanted to go back to the basics and build a modern magazine rack. We’ve had a tendency to add angles to everything lately, so it was nice to keep this design nice and sleek.

Let’s start DIYing!

Materials and Tools:

- Fiskars Powercut Snips

- Fiskars Precision Hand Saw

- Fiskars Hammer and Nail Starter

- Sewing Machine

- Tape Measure

- Faux Leather (we got ours from Hobby Lobby)

- ⅝” Square Dowels

- Black Spray Paint

- 1.25” Nails

- Wood Glue

Step 1: Make your cuts.

For this magazine rack, we cut 10 pieces to 15.75” and 4 pieces to 7” using the Fiskars Precision Hand Saw. T Once we cut the first piece, we used it as a guide for the remainder. By placing the already cut piece on top of the to-be-cut dowel, we were able to get a straight cut with accurate sizing without much measuring.

Step 2: Dry fit your pieces.

Once you get everything cut, it’s important to dry fit your magazine rack to make sure one piece didn’t end up too small or too large. Once everything fits together well, you can move onto the next step.

Step 3: Paint your wood.

We chose spray paint to quickly paint our wood black.

Step 4: Cut your leather.

While the spray paint is drying, cut two pieces of faux leather that are the same size. The Fiskars Powercut Snips make the cuts as smooth as butter and don’t fray the fabric.

We cut ours down to 16x26 with the hopes of it ending up as 14x24 as we sewed and cut the excess.

I’d recommend the 14” measurement, but after seeing the project come together fully, you might want to add a few inches to the longer measurements if you want your leather to hang closer to the floor.

Step 5: Sew your leather.

I’m not going to pretend I’m an expert sewer. My lines are never straight and my fabric always ends up not being flat, but I’m okay enough to sew two pieces together. If you need sewing instructions, I’d recommend looking up sewing tutorials on Hometalk :)

Since my lines are never straight, I end up cutting about ¼” from my stitches all the way around rather than cutting an actual rectangle. Luckily, the Powercut Snips make it easy to get clean lines, even though they weren’t perfectly straight.

The last step is to sew a loop on either side that will allow the leather to slide onto one of the dowels. Grab a dowel to make sure you make the loop big enough before you sew it.

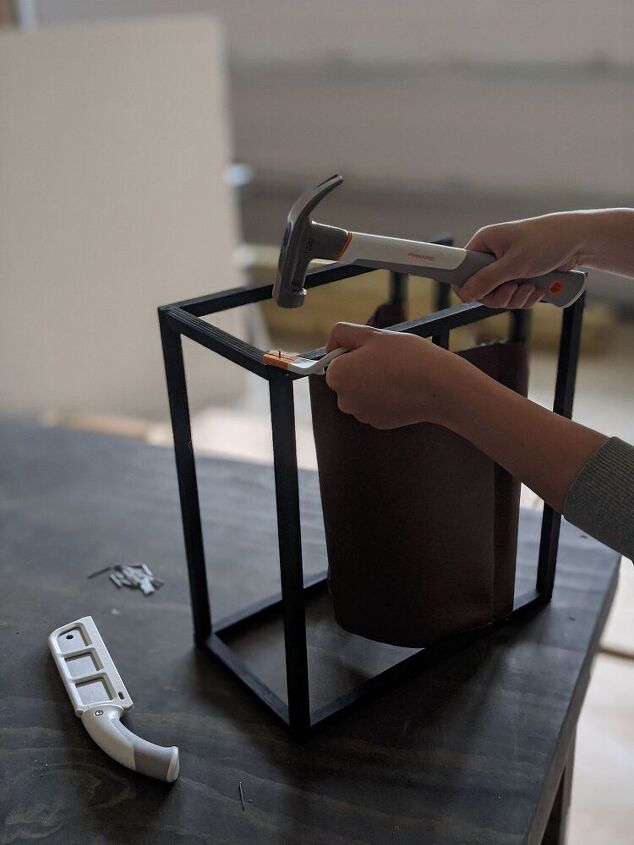

Step 6: Assemble your magazine rack.

Start by gluing and nailing together the side, which is made up of two 7” pieces and two 15.75” piece. The bottom 7” piece should be flush with the bottom while the upper 7” piece should be 3” from the top of the magazine holder.

Once you assemble both sides, glue and nail in the three 15.75” on one side. The pieces should be lined up with the top, the bottom, and then 3” from the top. The Precision Nail Starter especially comes in handy at this stage since you have to position the nail precisely to not hit the nails that are already holding the side together. Repeat on the other side.

Before nailing in the second side, slide your leather onto the long middle dowels. Once the leather is in place, you can glue and nail the side on to complete the magazine rack.

There you have it! Now you know how to make a sophisticated leather magazine rack. Despite my poor sewing skills, it still turned out pretty well. That just goes to show that you can still find joy in creating even if you don’t feel 100% confident in every step of the way.

In fact, trying something new and stepping outside of your comfort zone adds a whole new level of appreciation when you’re able to finally see the end result.

Enjoyed the project?

Resources for this project:

See all materials

Frequently asked questions

Have a question about this project?

You listed the total cost of only $30 for the entire project.

Which materials did you have before starting, and what was the cost of the four Fiskars tools that shown in the picture?

What is that tool you are holding that is keeping the nail straight?

Love this idea by the way!!