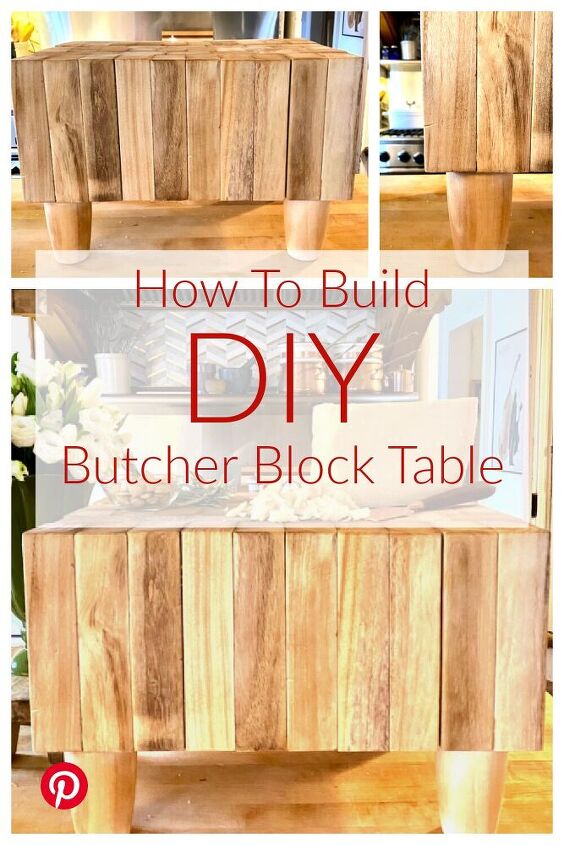

DIY Butcher Block Table Prototype

Want to build your own butcher block table? Create a butcher block table prototype first to iron out the kinks and get the logistics right.

For years I have wanted one of those old butcher block tables. You know, the ones that are typically square and have those sturdy beam-like legs. I see them all the time at antique shops and online at places like Facebook Marketplace and eBay. Thing is, is that most that I find are in really tough shape, and naturally so because they’re old or they just haven’t been well taken care of. I would like to have one in the Butler’s pantry for a little extra prep area and a little bit of just because.

On the rare occasion that I find a butcher block table that is in great shape, it’s a bazillion dollars and more that I would like to spend for a “just because” piece of furniture. Also, when I started measuring and getting down to the nitty gritty of planning, the typical size of such table is too big for the space. Clearly, this calls for a DIY project. Of course I could make one, I thought to myself. Why not? I’d build the exact size I wanted / needed, how hard could it be?? But, before I build the real deal, I would need to iron out the kinks.

In the designer’s world, whether it’s fashion, furniture, architecture, etc., prototypes are created for the initial design. Samples, if you will, to work on and tweak to make the end result just right. It only made sense to build my own butcher block table prototype.

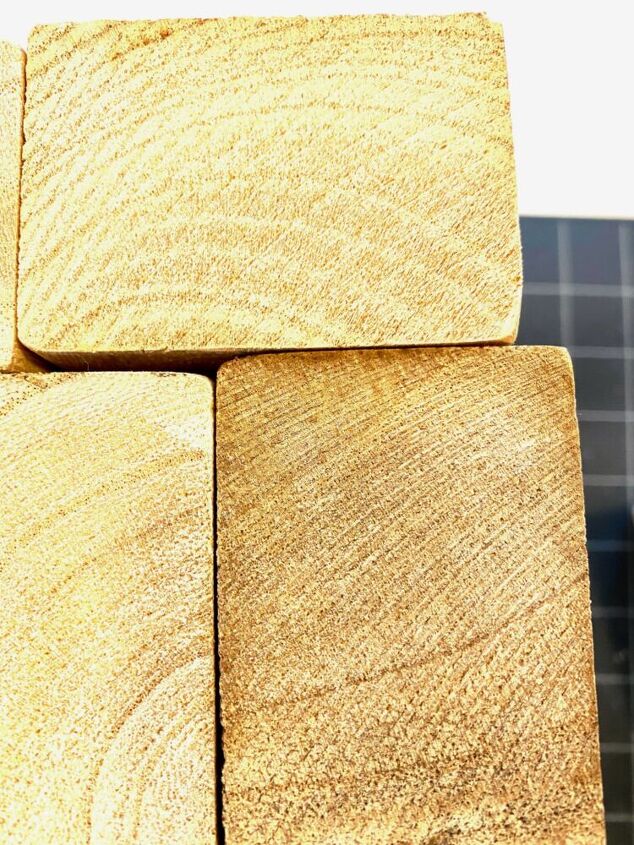

We had some leftover pine from the Garden House build, and I asked Sean to cut into 4-inch blocks. A little puny for a table prototype, but it was when I stubbed my toe (and spewed a few choice words) on a life-size Jenga game outside of M & C’s rooms, that I quickly decided to turn this game into a table.

After doing a little research, I determined that wood glue would be the best way to bond the wood pieces together. I started by laying the wood pieces, and playing around with pattern, until I came up with this one.

Next, time to glue. I applied a wavy stream of glue, then used a small brush to level it and brush it just shy of the edges. For the second layer, I brushed the glue on two sides, bonding the wood layers together.

When all of the wood was glued, I placed a heavy box on top as a make-shift clamp, and let the glue set up for 24 hours. Then, I took a 100 grit sand paper and sanded the entire surface of the butcher block, then followed it up with a 220 grit to get the surface really smooth.

For the legs of the table, I found these wooden feet at Home Depot, and screwed them into the bottom of the butcher block. From there, I wiped down the block and applied Boos Block Mystery Oil to the entire surface. I used this oil because it is food safe.

I learned three major things from building this prototype:

- All sides of each piece of wood need to be 90 degree angles. The wood I used, does not, and as you can see there are small gaps between some pieces.

- Because there are gaps, I cannot use it as a cutting board. If food gets lodged in a gap (except for the occasional cracker crumb), it would be almost impossible to clean and I don’t want spoil or rot between the cracks.

- If I decide to build a custom size butcher block table, I may need to entertain using a biscuit joiner and wood glue together, and for sure, I’ll need to invest in legit big clamps to secure everything together.

So the jury is out on building a large butcher block table. I do highly recommend if you are thinking about building something like this, that you start with a prototype first. Building a butcher block table is a big commitment for a novice like me, or any first-time-furniture-builder-wannabe.

On the really bright side, I now have a mini butcher block table that makes for an amazing serving piece that absolutely makes a statement.

Now, where the heck am I going to put it?

This post contains affiliate links.

Enjoyed the project?

Resources for this project:

See all materials

Comments

Join the conversation

-

Irene Kogan

on Feb 07, 2022

Irene Kogan

on Feb 07, 2022

it is a great accent table to put your knickknacks on, but i sincerely hope you would never use it for food, especially cutting anything.

Pine is too porous to be food-grade, not to mention that you did not seal the tabletop, and after one use, you will end up with bacteria growing in all the crevices and pores

-

-

LAURIE STODDARD

on Feb 08, 2022

LAURIE STODDARD

on Feb 08, 2022

My husband made me this butcher block cutting board with a drawer, 20+ years ago. The wood is lengthwise for a better look. He put dowels through it to keep it tight and food out. The finish is linseed oil for food safety. The drawer is dovetailed and has wooden slides on it, to prevent it from sticking we put wax on it.

I think that if she put a piece of tempered glass on top it would be safe to use for food preparation. Otherwise it will be a good conversation starter in her kitchen.

-

-

Frequently asked questions

Have a question about this project?

I am certainly no expert, but are you supposed to use the end grain of the wood? I would think that it would make the surface too porous and it would suck up liquids really easily.

Carolyn

PS It turned out really nice even for a first project.

I would purchase a used planer I see them for sale much cheaper! I still love your project! maybe epoxy would help but that would be too glossy?